Wacker Neuson active diagnostic tool codes, particularly the G100 series, are essential for anyone working with these machines. Whether you’re a seasoned technician or a DIY enthusiast, understanding these codes can save you time, money, and frustration. This comprehensive guide will delve into the intricacies of G100 codes, providing you with the knowledge to diagnose and address issues effectively.

Decoding the Wacker Neuson Active Diagnostic Language

The active diagnostic system in Wacker Neuson equipment acts as the machine’s internal communication network. When a problem arises, the system generates specific codes, like the G100 series, that pinpoint the source of the issue. Think of these codes as the machine’s way of telling you exactly what’s wrong.

What Does the G100 Code Series Represent?

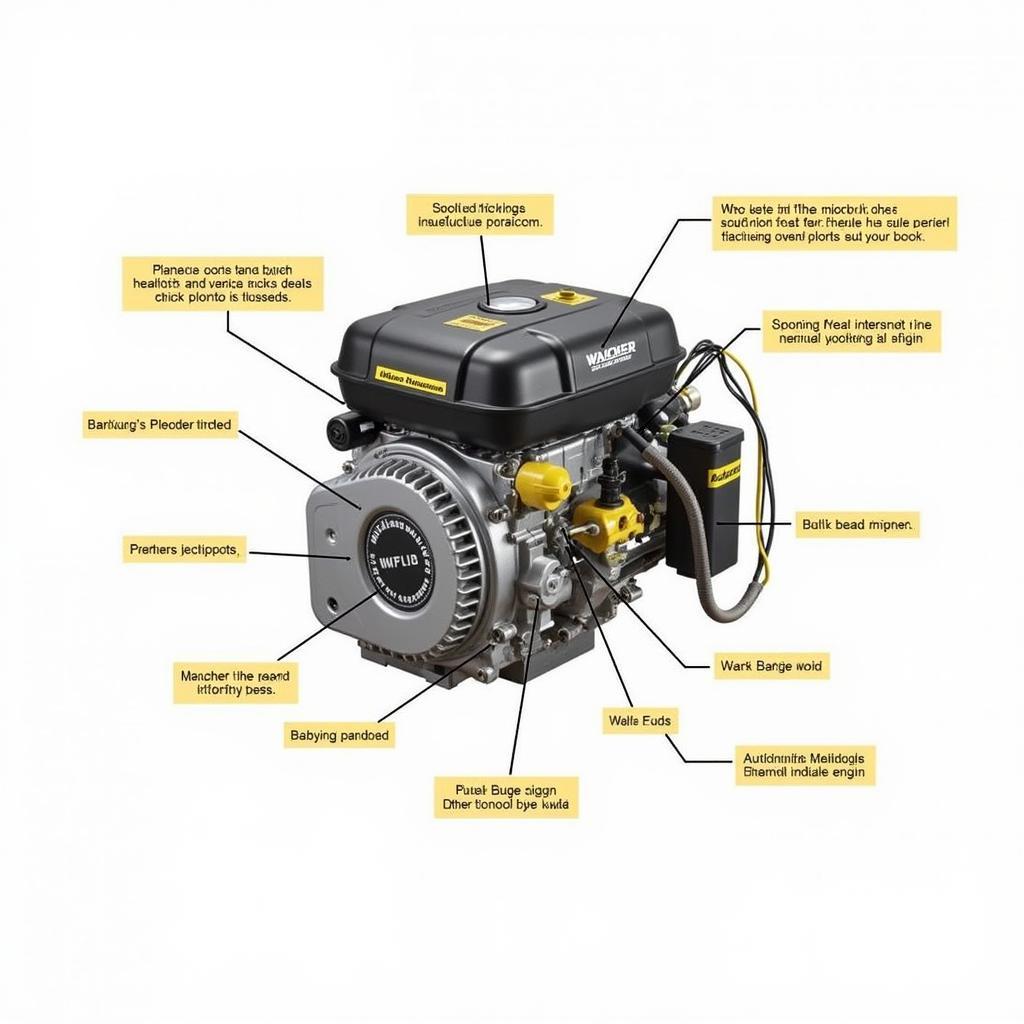

The G100 code series specifically relates to the engine control unit (ECU) and its associated components. This includes sensors, actuators, and wiring harnesses responsible for managing various engine functions.

Wacker Neuson Engine Diagram

Wacker Neuson Engine Diagram

Example:

Let’s say you encounter the code “G100 – Engine Speed Sensor Circuit Malfunction.” This code immediately tells you there’s an issue with the sensor responsible for monitoring engine speed, or the wiring connecting it to the ECU.

Common G100 Codes and Troubleshooting Tips

While the specific G100 codes vary depending on the Wacker Neuson model, some commonly encountered codes include:

- G101: Crankshaft Position Sensor Circuit Malfunction

- G102: Vehicle Speed Sensor Circuit Malfunction

- G105: Engine Coolant Temperature Sensor Circuit Malfunction

- G107: Intake Air Temperature Sensor Circuit Malfunction

- G108: Manifold Absolute Pressure Sensor Circuit Malfunction

Troubleshooting G100 Codes

- Consult the Operator’s Manual: Always refer to the machine’s specific operator’s manual for detailed code definitions and troubleshooting steps tailored to your model.

- Visual Inspection: Begin by visually inspecting the components related to the code. Check for loose connections, damaged wiring, or faulty sensors.

- Multimeter Testing: Use a multimeter to check the continuity and resistance of wiring harnesses and sensors associated with the code.

- Diagnostic Software: For more in-depth diagnostics, utilize Wacker Neuson’s diagnostic software. This software can provide live data streams, actuator tests, and advanced troubleshooting capabilities.

Expert Insight:

“Don’t underestimate the power of a good visual inspection,” says John Miller, a senior technician with 20 years of experience working on Wacker Neuson equipment. “Often, a loose connection or a damaged wire is the culprit behind a G100 code.”

The Importance of Using Genuine Wacker Neuson Parts

When replacing faulty components, always opt for genuine Wacker Neuson parts. Using aftermarket or incompatible parts can lead to further issues and may even void your warranty.

Seek Professional Assistance When Needed

While understanding G100 codes can empower you to handle minor issues, don’t hesitate to seek professional help from a certified Wacker Neuson technician for complex problems or if you’re uncomfortable performing certain repairs.

Conclusion

Mastering the language of Wacker Neuson active diagnostic tool codes, especially the G100 series, is crucial for efficiently diagnosing and resolving engine-related issues. By understanding these codes and following the recommended troubleshooting steps, you can keep your Wacker Neuson equipment operating at peak performance. If you are located near Cicero, IL, you can call us at +1 (641) 206-8880 or visit us at 1615 S Laramie Ave, Cicero, IL 60804, USA, and our team will assist you with any questions.