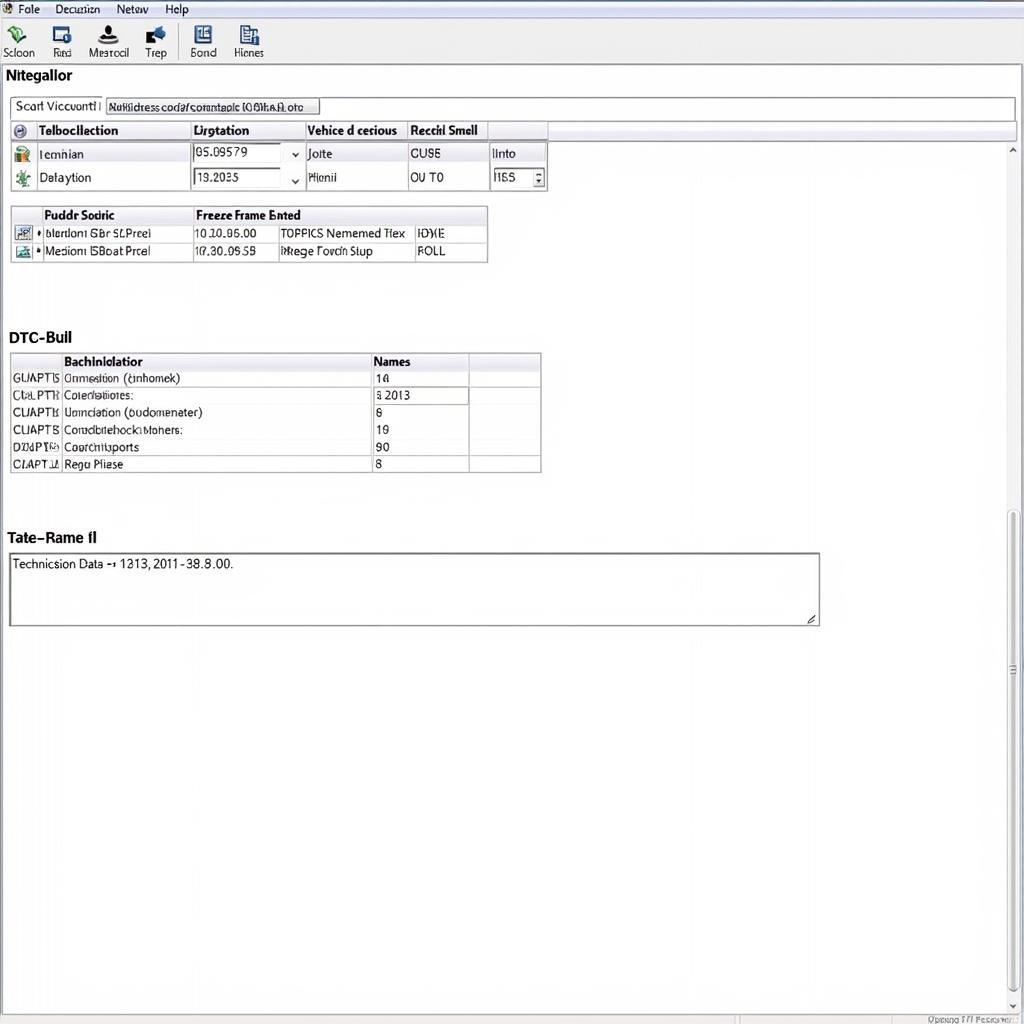

A Scan Tool Worksheet is an essential tool for any automotive technician. It provides a standardized format for documenting diagnostic trouble codes (DTCs), freeze frame data, and other relevant information retrieved from a vehicle’s onboard computer using a scan tool.

Understanding the Importance of Scan Tool Worksheets

Scan Tool Worksheet Example

Scan Tool Worksheet Example

Imagine this: a car rolls into your shop with the check engine light glaring. A quick scan reveals a cryptic code – P0302. What’s next? This is where a scan tool worksheet comes into play.

A scan tool worksheet helps you:

- Organize information: It provides a structured way to record DTCs, their descriptions, freeze frame data, and other crucial details, preventing information overload.

- Track progress: Documenting each step of the diagnostic process, from initial code retrieval to final repair verification, helps maintain a clear record of your work.

- Improve accuracy: By systematically collecting and analyzing data, you can reduce the likelihood of misdiagnosis and ensure a more efficient repair process.

- Enhance communication: A well-structured worksheet serves as a communication tool between technicians, service advisors, and customers, fostering transparency and trust.

Key Components of a Scan Tool Worksheet

Scan Tool Connected to a Car's OBD-II Port

Scan Tool Connected to a Car's OBD-II Port

While the specific layout may vary, a comprehensive scan tool worksheet typically includes:

- Vehicle Information: This section captures essential details about the vehicle, such as VIN, year, make, model, engine type, and mileage.

- Customer Information: Recording customer contact details and a brief description of their concerns ensures efficient communication and personalized service.

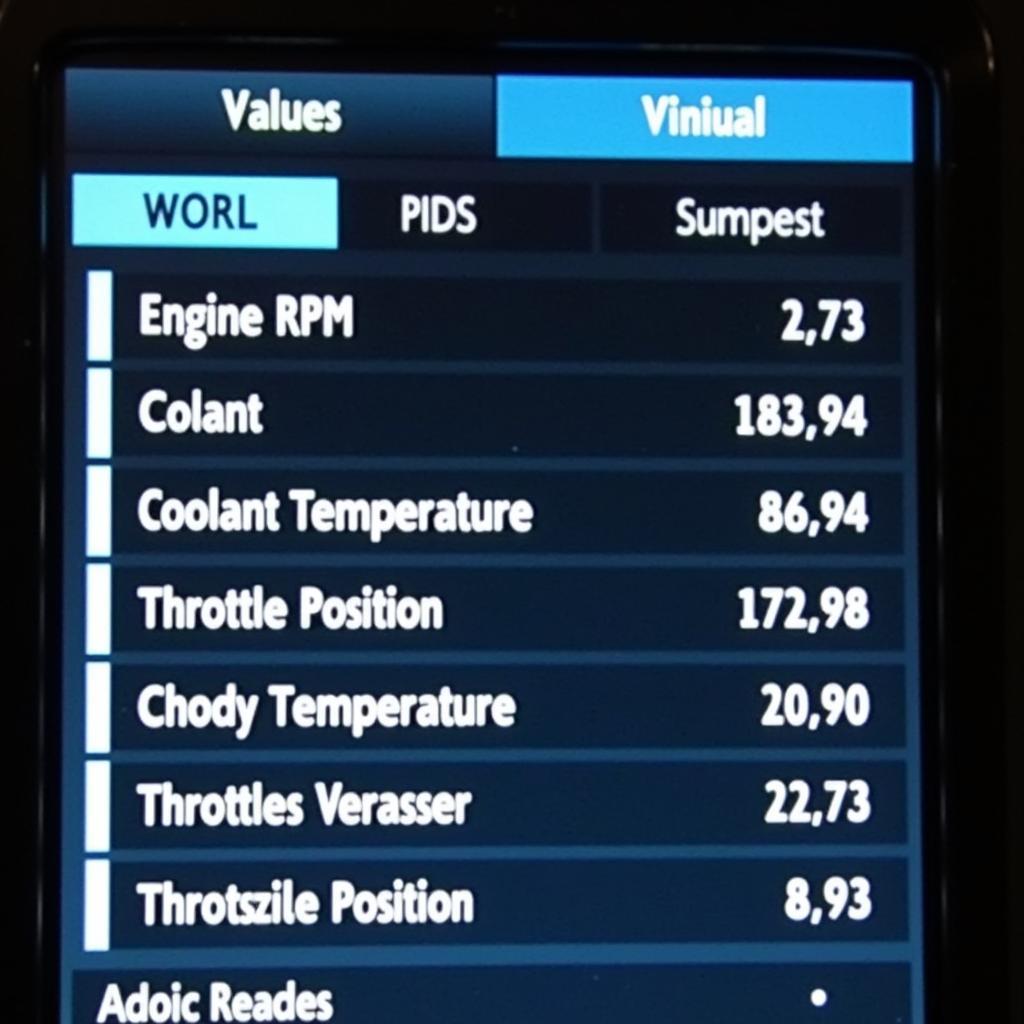

- Diagnostic Trouble Codes (DTCs): This section lists all retrieved DTCs, along with their descriptions.

- Freeze Frame Data: This snapshot of the engine’s operating conditions at the time the DTC was set provides valuable clues about the root cause of the problem.

- Testing Procedures and Results: This section documents the various tests performed, including voltage checks, sensor readings, and component activations, along with their corresponding results.

- Repair Recommendations and Actions Taken: This is where you outline the recommended repair procedures based on your diagnosis and record the specific actions taken to address the issue.

- Verification: After completing the repair, it’s crucial to re-scan the system and confirm that all DTCs have been cleared and the issue is resolved.

- Parts and Labor: This section details the parts used and the labor hours spent on the repair, enabling accurate invoicing and cost analysis.

“A well-maintained scan tool worksheet is like a detective’s notebook. It helps you connect the dots, identify patterns, and ultimately crack the case,” says John Miller, a veteran automotive diagnostician with over 20 years of experience. “It’s not just about fixing the immediate problem; it’s about understanding the ‘why’ behind it.”

Tips for Effective Scan Tool Worksheet Utilization

Mechanic Analyzing Scan Tool Data on a Tablet

Mechanic Analyzing Scan Tool Data on a Tablet

Here are some practical tips to maximize the effectiveness of scan tool worksheets:

- Use a Consistent Format: Adopt a standardized worksheet template for all diagnostic procedures to ensure consistency and easy retrieval of information.

- Be Thorough and Accurate: Record all relevant data, even seemingly insignificant details. Double-check entries to minimize errors.

- Utilize Abbreviations Sparingly: While abbreviations can save time, use them judiciously to avoid confusion and ensure clarity, especially for less experienced technicians.

- Don’t Rely Solely on DTCs: DTCs are starting points, not definitive answers. Use your knowledge, experience, and additional testing to pinpoint the root cause.

- Embrace Digital Solutions: Consider using digital scan tools and software that integrate with shop management systems for seamless data transfer and record-keeping.

Conclusion

Scan tool worksheets are invaluable assets in modern automotive diagnostics. They streamline the diagnostic process, promote accuracy, and enhance communication. By embracing these tools and following the tips outlined above, technicians can elevate their diagnostic skills and deliver efficient, high-quality repairs.

Need help choosing the right scan tool or software for your workshop? Contact ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA. We’re here to help you optimize your diagnostic workflow and keep vehicles running smoothly.

FAQs

1. Are scan tool worksheets mandatory?

While not legally mandatory, many repair shops and dealerships require their technicians to use scan tool worksheets for internal quality control, training, and documentation purposes.

2. Can I create my own scan tool worksheet?

Yes, you can create your own template or customize existing ones to suit your specific needs and preferences.

3. Are there digital alternatives to paper-based worksheets?

Yes, several software programs and apps offer digital scan tool worksheet functionalities, allowing for electronic storage, retrieval, and sharing of data.

4. What are the benefits of using digital scan tool worksheets?

Digital worksheets offer numerous advantages, including improved data organization, reduced paper waste, easier sharing and collaboration, and integration with other shop management systems.

5. How long should I keep scan tool worksheets?

It’s generally recommended to keep repair records, including scan tool worksheets, for a minimum of three years, although specific requirements may vary depending on local regulations.

Pingback: Demystifying Scan Tool Abbreviations: A Comprehensive Guide - Car Scan Tool

Pingback: List of Scan Tool Codes Abbreviations: A Comprehensive Guide - Car Scan Tool