Preload on Morel 4603 lifters is a crucial aspect of achieving optimal performance and longevity in high-performance engines. Setting the correct preload ensures proper valve operation and prevents issues like valve float, excessive wear, and even catastrophic engine failure. This guide, inspired by the expertise of Scott Foxwell and other industry leaders, will delve into the intricacies of setting preload on Morel 4603 lifters, providing you with the knowledge to confidently tackle this critical task.

Understanding Preload on Morel 4603 Lifters

Morel 4603 lifters are a popular choice for performance builds due to their robust construction and ability to handle aggressive camshaft profiles. However, these lifters require precise preload adjustment to function correctly. Preload is essentially the amount the lifter plunger is compressed when the valve is closed. This compression ensures the lifter maintains constant contact with the camshaft lobe, allowing for accurate valve timing and lift. Incorrect preload can lead to a variety of issues, from noisy valvetrain operation to severe engine damage.

Why is Preload so Important for Morel 4603 Lifters?

Proper preload is vital for Morel 4603 lifters because it directly impacts valve train stability and longevity. Too little preload can result in excessive lifter pump-up and valve float at high RPM, leading to power loss and potential valve damage. Conversely, too much preload can cause the valves to stay slightly open, leading to compression loss, overheating, and even burnt valves.

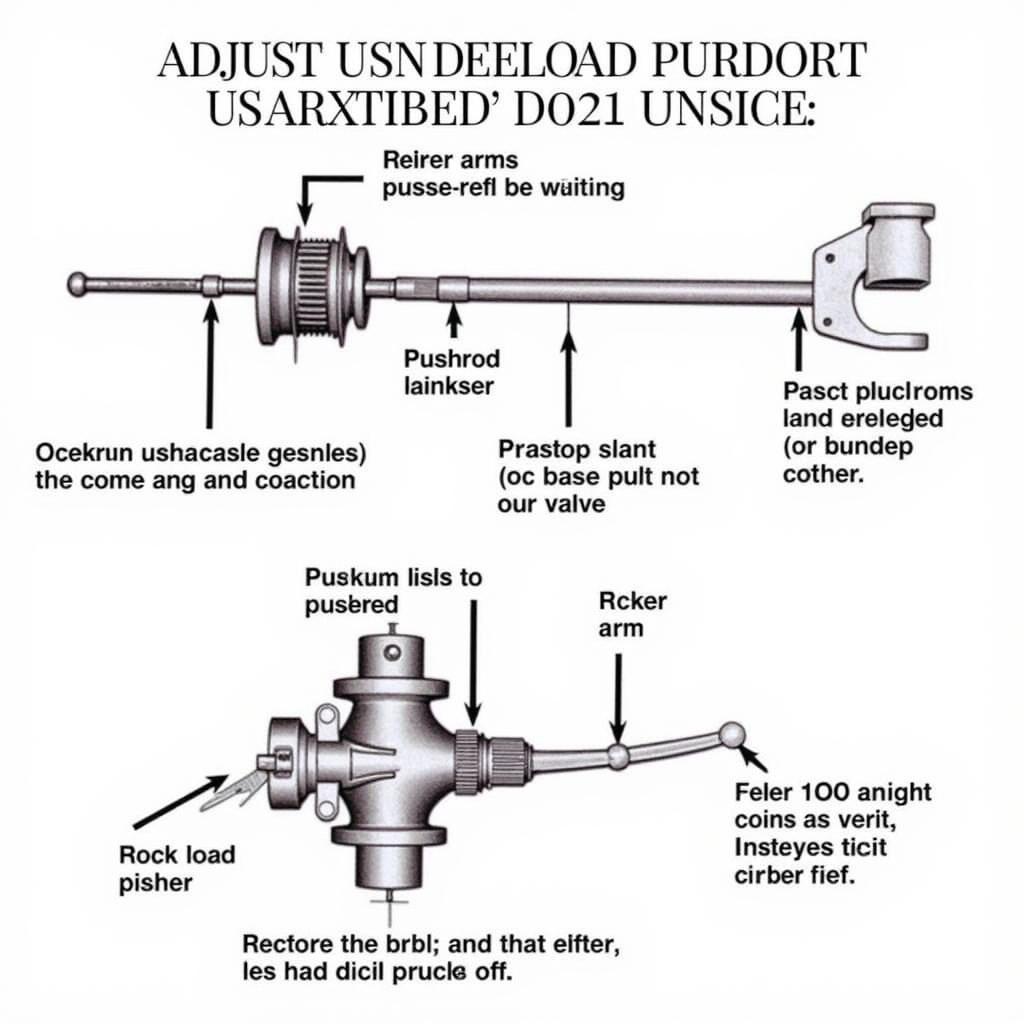

Morel 4603 Lifter Preload Adjustment

Morel 4603 Lifter Preload Adjustment

How to Set Preload on Morel 4603 Lifters

Setting preload on Morel 4603 lifters requires precision and attention to detail. Here’s a step-by-step guide to help you through the process:

- Gather your tools: You’ll need a pushrod length checker, feeler gauges, a torque wrench, and the appropriate socket for your rocker arm nuts.

- Determine your target preload: Consult the manufacturer’s specifications for your specific Morel 4603 lifter and camshaft combination to determine the recommended preload. This is typically expressed in thousandths of an inch.

- Install the lifter and pushrod: Place the lifter in its bore and insert the pushrod, ensuring it’s seated correctly in the lifter and rocker arm.

- Adjust the rocker arm: Tighten the rocker arm nut to zero lash (the point where all play is removed from the valvetrain).

- Measure the preload: Using a pushrod length checker and feeler gauges, measure the preload. Rotate the pushrod while tightening the checker until you achieve the desired preload measurement with the feeler gauge.

- Calculate the required pushrod length: Based on the measurement obtained from the pushrod length checker, calculate the correct pushrod length needed to achieve your target preload.

- Install the correct pushrod: Once you have determined the correct pushrod length, install it and recheck the preload to ensure accuracy.

- Torque the rocker arm nuts: Torque the rocker arm nuts to the manufacturer’s specified torque.

Common Mistakes to Avoid

- Not consulting the manufacturer’s specifications: Always refer to the manufacturer’s recommendations for your specific components.

- Using incorrect tools: Using improper tools can lead to inaccurate measurements and improper preload.

- Rushing the process: Take your time and double-check your measurements to ensure accuracy.

“Accurate preload is paramount for optimal performance,” says Scott Foxwell, a renowned expert in automotive diagnostics and performance tuning. “A small deviation can have significant consequences on engine efficiency and longevity.”

Conclusion

Setting the preload on Morel 4603 lifters is a critical step in building a high-performance engine. By following this guide and taking your time, you can ensure proper valve train operation, maximizing performance and longevity. Remember to always consult the manufacturer’s specifications for your specific application. For professional diagnostic tools and expert advice, contact ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA.

“Don’t underestimate the importance of accurate preload,” adds Foxwell. “It’s a small detail that can make a big difference in the overall performance and reliability of your engine.”

FAQ

-

What is preload on a lifter? Preload is the amount the lifter plunger is compressed when the valve is closed.

-

Why is correct preload important? Correct preload ensures proper valve operation and prevents engine damage.

-

What tools do I need to set preload? You need a pushrod length checker, feeler gauges, and a torque wrench.

-

Where can I find the recommended preload for my lifters? Consult the manufacturer’s specifications.

-

What happens if the preload is too tight? Too much preload can cause burnt valves and compression loss.

-

What happens if the preload is too loose? Too little preload can cause valve float and power loss.

-

Where can I get help with setting lifter preload? Contact ScanToolUS for expert advice and diagnostic tools.