A Memory Diagnostics Tool Hardware Problem can be a nightmare for car owners and technicians alike. These tools are essential for diagnosing a wide range of automotive issues, and a malfunction can bring the entire diagnostic process to a grinding halt. This comprehensive guide delves into the common hardware problems associated with memory diagnostics tools, providing you with the knowledge to troubleshoot and potentially resolve these issues.

Understanding Memory Diagnostics Tools

Before we dive into the hardware problems, it’s crucial to understand what these tools are and how they function. In essence, a memory diagnostics tool is a specialized electronic device that interfaces with your car’s computer system, primarily the Engine Control Unit (ECU), to retrieve diagnostic trouble codes (DTCs), real-time data, and other vital information. This data helps pinpoint the root cause of various car problems, ranging from engine misfires to faulty sensors.

Common Hardware Problems

Just like any electronic device, memory diagnostics tools are susceptible to hardware malfunctions. Here are some common issues you might encounter:

1. Connection Problems

One of the most frequent culprits is a faulty connection between the tool and the vehicle’s OBD-II port. This can be due to:

- Damaged OBD-II Port: Physical damage to the port, like bent pins or debris accumulation, can obstruct the connection.

- Faulty Cable: A damaged or worn-out cable connecting the tool to the port can disrupt data transmission.

- Loose Connection: A loose connection, even if seemingly secure, can lead to intermittent communication failures.

2. Power Supply Issues

Memory diagnostics tools require a stable power supply, usually drawn directly from the vehicle’s OBD-II port. Problems can arise due to:

- Insufficient Vehicle Battery Voltage: A weak or discharged car battery might not provide enough power to the tool.

- Blown Fuse: A blown fuse in the vehicle’s fuse box, particularly one related to the OBD-II port, can cut off power to the tool.

3. Internal Hardware Failure

While less common, internal hardware components within the memory diagnostics tool itself can fail. This might involve:

- Malfunctioning Processor: The tool’s central processing unit, responsible for data processing and communication, can malfunction.

- Faulty Memory: The tool’s internal memory, used for storing software and data, can become corrupted or fail.

- Damaged Components: Physical damage from drops, impacts, or exposure to extreme temperatures can harm internal components.

Troubleshooting and Solutions

Facing a memory diagnostics tool hardware problem? Here’s a systematic approach to troubleshooting and potential solutions:

-

Check the Basics:

- Ensure the vehicle’s ignition is switched to the “On” position (engine not necessarily running).

- Verify that the tool is properly connected to the OBD-II port.

- Inspect the OBD-II port and the tool’s cable for any visible damage.

-

Test with Another Vehicle:

- If possible, try connecting the tool to a different vehicle to rule out vehicle-specific issues.

-

Check Vehicle Battery Voltage:

- Use a multimeter to check the vehicle’s battery voltage. A reading below 12 volts might indicate a weak battery.

-

Inspect Vehicle Fuses:

- Consult the vehicle’s owner’s manual to locate the fuse box and identify the fuse related to the OBD-II port. Replace if blown.

-

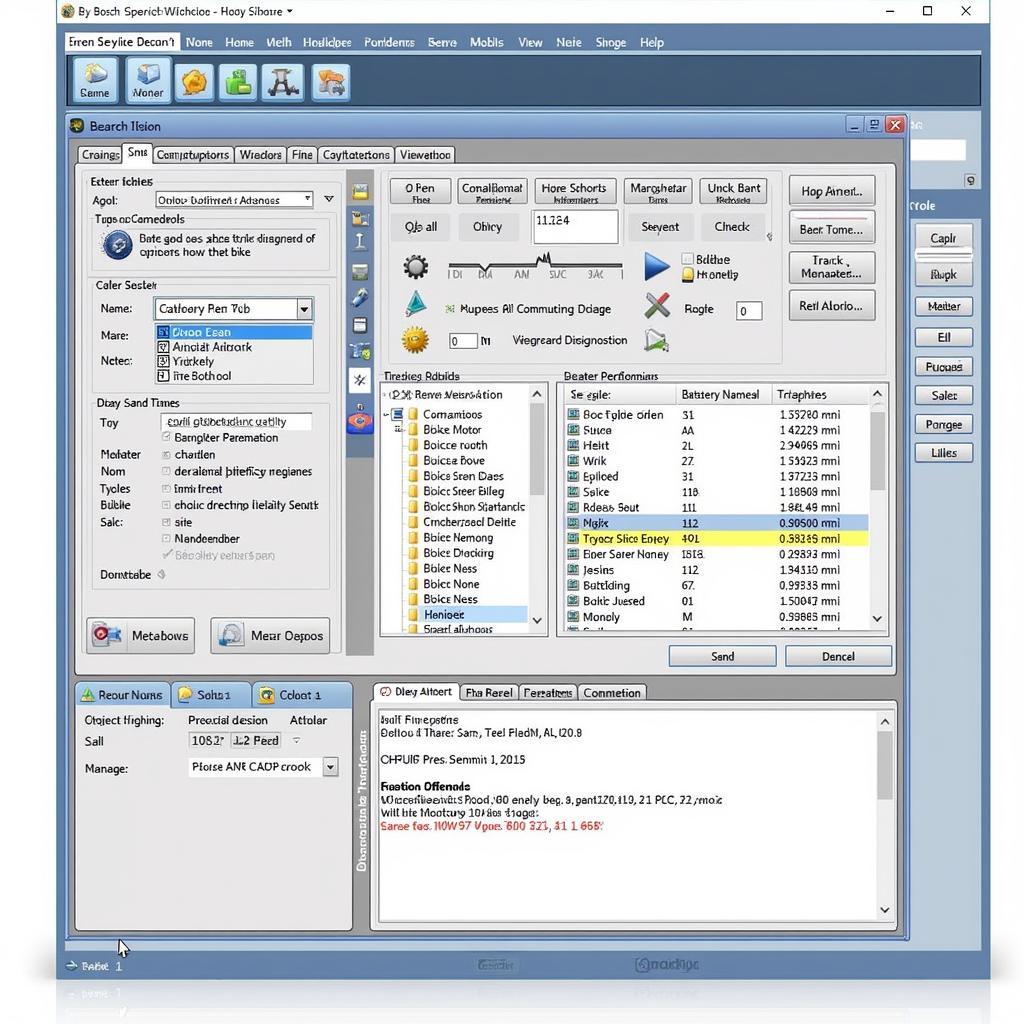

Update Tool Firmware:

- Connect the tool to a computer and check the manufacturer’s website for any available firmware updates. Updating the firmware can resolve software-related glitches.

Technician Updating Tool's Firmware

Technician Updating Tool's Firmware

- Contact Manufacturer Support:

- If the problem persists, contact the memory diagnostics tool manufacturer’s support team for further assistance. They might offer repair services or replacement options.

Preventing Hardware Problems

Taking preventive measures can significantly reduce the risk of encountering hardware problems with your memory diagnostics tool:

- Handle with Care: Always handle the tool with care, avoiding drops, impacts, and exposure to extreme temperatures or moisture.

- Store Properly: When not in use, store the tool in a clean, dry, and dust-free environment, preferably in its protective case.

- Regular Updates: Regularly check for and install firmware updates from the manufacturer’s website to ensure optimal performance and address potential software issues.

Expert Insights

“Investing in a high-quality memory diagnostics tool is crucial for accurate and efficient vehicle diagnostics,” says John Miller, a seasoned automotive electrical engineer with over 20 years of experience. “However, even the best tools require proper care and maintenance. Regularly inspecting your tool for physical damage, ensuring a stable power supply, and keeping the firmware updated can significantly extend its lifespan and prevent costly downtime.”

Conclusion

Memory diagnostics tools are indispensable for diagnosing and resolving automotive issues. Understanding common hardware problems and adopting a systematic troubleshooting approach can save you time, money, and frustration. Remember to handle your tools with care, perform regular maintenance, and seek professional assistance when needed.

Need help with your car diagnostics? Contact ScanToolUS for expert advice and top-notch diagnostic solutions. Call us at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA.

FAQs

1. Can I use any memory diagnostics tool for my car?

No, not all tools are compatible with all car makes and models. Ensure the tool you choose supports your vehicle’s specific make, model, and year.

2. What is the OBD-II port?

The OBD-II port is a standardized 16-pin connector found in most vehicles manufactured after 1996. It allows external diagnostic tools to communicate with the car’s computer system.

3. My memory diagnostics tool is frozen. What should I do?

Try disconnecting the tool from the vehicle and power source, wait for a few minutes, and reconnect. If the issue persists, contact the manufacturer’s support.

4. Can I repair the tool myself?

Unless you have the technical expertise and specialized equipment, it’s not recommended to attempt DIY repairs on electronic diagnostic tools.

5. How often should I update the tool’s firmware?

Check the manufacturer’s website for firmware update recommendations. Typically, updating once or twice a year is good practice.