Troubleshooting a cranky marine diesel engine can feel like navigating uncharted waters. But with the right Marine Diesel Engine Diagnostic Tools, you can chart a course to smooth sailing. Whether you’re a seasoned mechanic or a boat owner looking to tackle DIY repairs, understanding and utilizing these tools can save time, money, and unnecessary headaches.

Why Invest in Marine Diesel Engine Diagnostic Tools?

Gone are the days of relying solely on intuition and a mechanic’s stethoscope to diagnose engine problems. Modern marine diesel engines are complex systems controlled by sophisticated electronics. Marine diesel engine diagnostic tools act as your eyes and ears, providing insights into the inner workings of your engine and helping pinpoint issues with precision.

Here’s how these tools translate to real-world benefits:

- Accurate Diagnosis: Identify the root cause of problems quickly and accurately, eliminating guesswork and potentially costly trial-and-error repairs.

- Time Savings: Streamline the troubleshooting process, reducing downtime and getting your boat back on the water faster.

- Cost-Effectiveness: Prevent unnecessary repairs by precisely identifying faulty components, saving you money in the long run.

- Preventive Maintenance: Monitor engine performance and identify potential problems early on, preventing major breakdowns and extending the life of your engine.

- Enhanced Understanding: Gain a deeper understanding of your engine’s operation, empowering you to make informed decisions about maintenance and repairs.

Essential Marine Diesel Engine Diagnostic Tools

While a comprehensive toolbox might seem overwhelming, we’ll focus on the must-haves:

1. Marine Diagnostic Scanners: The Engine Whisperer

Marine Diagnostic Scanner

Marine Diagnostic Scanner

Consider marine diagnostic scanners your direct line of communication with your engine’s computer. These sophisticated tools plug into the engine’s Electronic Control Unit (ECU), reading and interpreting fault codes, real-time data, and performance parameters.

Key Features to Look For:

- Compatibility: Ensure the scanner supports your engine’s make, model, and year.

- Functionality: Look for features like reading and clearing fault codes, viewing live data streams, and performing actuator tests.

- User Interface: Choose a scanner with an intuitive interface and clear, easy-to-understand displays.

Expert Insight: “A quality marine diagnostic scanner is worth its weight in gold,” says Captain Mark Evans, a seasoned marine mechanic with over 20 years of experience. “It’s the first tool I reach for when diagnosing engine problems. The ability to read fault codes and monitor live data takes the guesswork out of repairs.”

2. Multimeters: The Electrical Detective

Multimeter Testing Engine

Multimeter Testing Engine

Even in the age of sophisticated electronics, a good old-fashioned multimeter remains indispensable. This versatile tool measures electrical properties like voltage, current, and resistance, helping you diagnose electrical faults in your engine’s starting, charging, and sensor systems.

Types of Multimeters:

- Analog: Offer basic functionality and affordability.

- Digital: Provide more accurate readings and often include additional features.

Essential Tips:

- Safety First: Always disconnect the battery before working on electrical components.

- Choose the Right Settings: Select the appropriate measurement range for the task.

3. Compression Testers: Gauging Engine Health

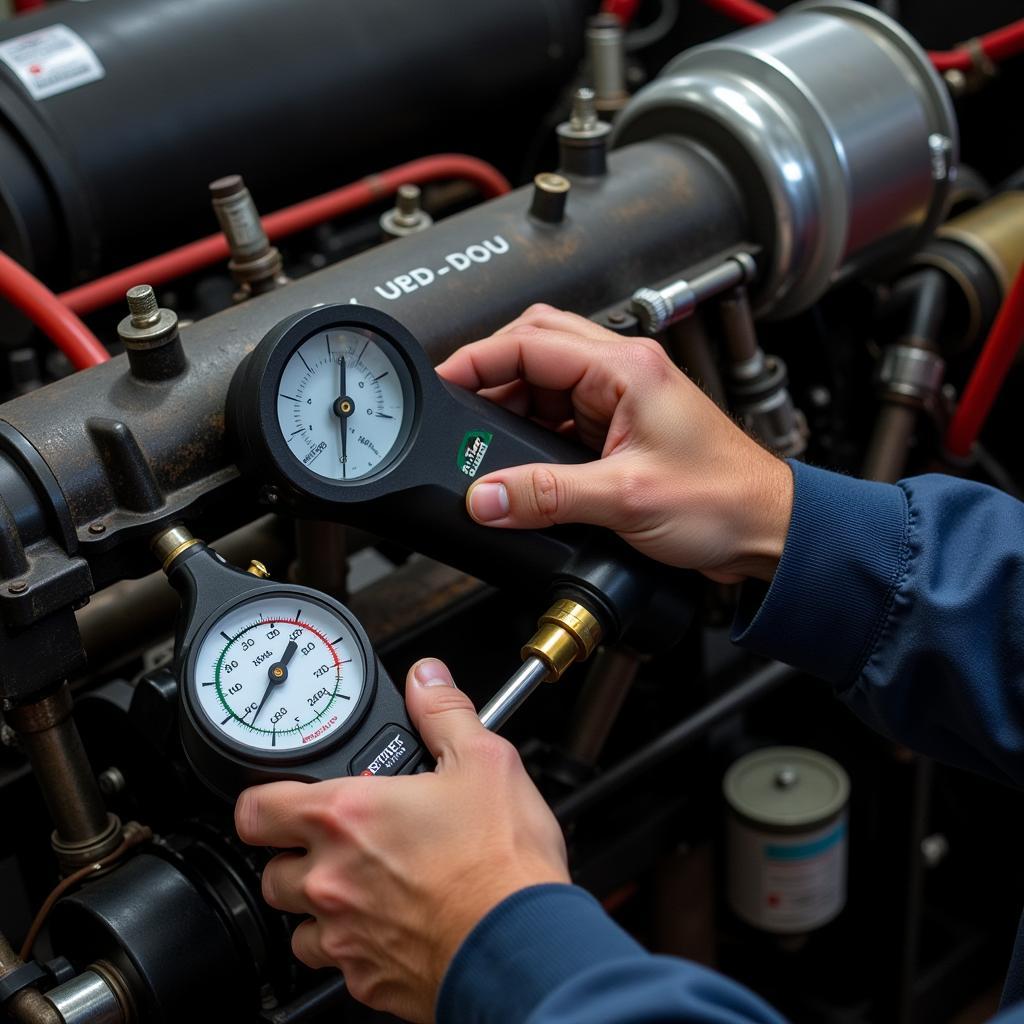

Compression Tester in Action

Compression Tester in Action

A compression tester measures the pressure inside each cylinder during the compression stroke. This vital test provides insights into the overall health of your engine’s cylinders, piston rings, valves, and head gasket. Low compression readings can indicate worn-out components or a blown head gasket.

How to Use:

- Warm up the engine to operating temperature.

- Disable the ignition or fuel injection system.

- Remove all spark plugs or injectors.

- Thread the compression tester into one cylinder at a time.

- Crank the engine for several revolutions.

- Record the highest pressure reading.

- Repeat for each cylinder.

Important Note: Compare the compression readings across all cylinders. Significant variations can indicate a problem.

4. Fuel Pressure Testers: Keeping the Fuel Flowing

Fuel delivery problems can manifest as hard starting, rough idling, or loss of power. A fuel pressure tester helps diagnose issues within the fuel system, such as a clogged fuel filter, weak fuel pump, or leaking injectors.

Types of Testers:

- Inline Testers: Installed between the fuel line and the fuel rail.

- Direct-Injection Testers: Connect directly to the fuel rail.

Safety Precaution: Fuel is flammable. Exercise extreme caution when working with the fuel system.

Conclusion: Navigating Engine Troubleshooting with Confidence

Marine diesel engine diagnostic tools empower you to take control of your engine’s health and maintenance. By investing in the right tools and understanding how to use them effectively, you’ll be well-equipped to diagnose and address engine problems. Remember, early detection and accurate diagnosis are key to smooth sailing and maximizing the life of your marine diesel engine.

Need help choosing the right tools for your needs? Contact the experts at ScanToolUS today! Our team of specialists is here to answer your questions and guide you towards the best solutions. Reach us at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA.