Understanding How To Read Scan Tool Data is crucial for anyone working on modern vehicles. Whether you’re a professional mechanic, a DIY enthusiast, or simply a curious car owner, this guide will equip you with the knowledge to interpret the information your scan tool provides and effectively diagnose car problems. Accessing this data opens a window into your vehicle’s inner workings, allowing you to pinpoint issues and avoid unnecessary repairs.

If you’re just starting out with OBD-II diagnostics, reading scan tool data can seem daunting. See our guide on basic scan tool data stream & read codes. However, by breaking down the process step by step, and understanding the common types of data displayed, you can gain valuable insights into your vehicle’s health. This guide will cover everything from understanding basic trouble codes to interpreting live data streams.

Decoding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes, or DTCs, are the foundation of scan tool data. These codes are standardized across most vehicles and provide a starting point for diagnosing issues. Each DTC consists of a five-character alphanumeric code that corresponds to a specific fault. The first character indicates the system affected (e.g., “P” for Powertrain, “B” for Body, “C” for Chassis, “U” for Network). Understanding the structure of DTCs is essential for accurate interpretation.

Understanding the Structure of DTCs

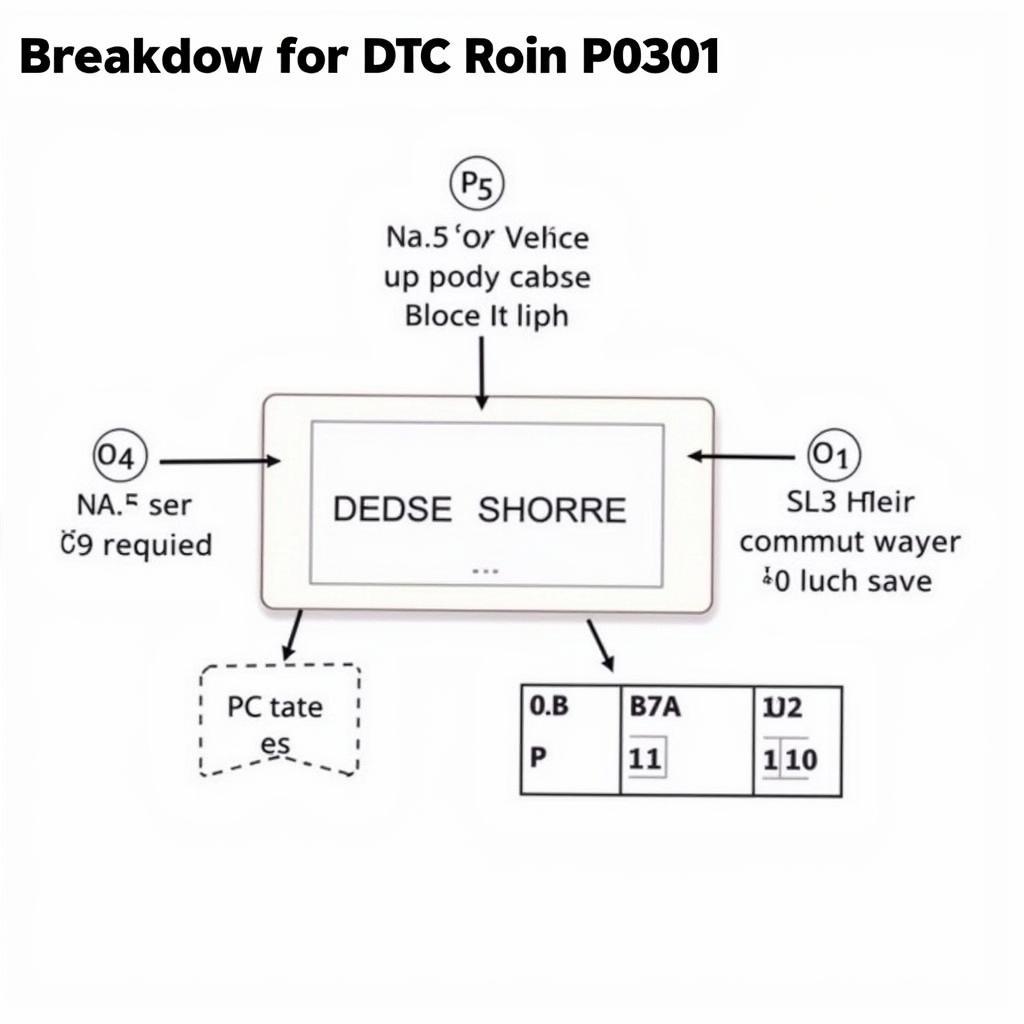

Let’s take the code P0301 as an example. The “P” indicates a powertrain issue. The “0” signifies a generic code, applicable across various manufacturers. The “3” refers to the specific subsystem within the powertrain (in this case, the ignition system). The final two digits pinpoint the specific fault, which in this case (01) means a misfire in cylinder 1. Learning to decipher this structure is your first step in effectively using scan tool data.

Decoding DTC Structure Example P0301

Decoding DTC Structure Example P0301

Interpreting Live Data from OBD-II Scanners

Live data provides real-time information about various sensors and systems in your vehicle. This dynamic data stream allows you to observe how different parameters change under various operating conditions, offering valuable insights beyond static DTCs. For a more detailed explanation, refer to how to read live data from obd ii scan tools.

Key Live Data Parameters to Monitor

Some essential live data parameters include engine speed (RPM), coolant temperature, oxygen sensor readings, fuel pressure, and throttle position. Monitoring these parameters can help you identify trends and anomalies that might not trigger a DTC but could indicate an underlying problem. For example, consistently low fuel pressure might suggest a failing fuel pump, even if no DTC is present.

“Being able to interpret live data is like having a conversation with your car,” says John Davis, a seasoned automotive diagnostician with over 20 years of experience. “It tells you what’s happening in real-time, allowing you to diagnose issues more accurately and efficiently.”

Using Freeze Frame Data for Advanced Diagnostics

Freeze frame data captures a snapshot of the vehicle’s operating conditions at the moment a DTC is set. This information can be invaluable in diagnosing intermittent problems that are difficult to reproduce. By examining the freeze frame data, you can gain insights into the factors that contributed to the fault.

Why is Freeze Frame Data Important?

Freeze frame data typically includes parameters like engine speed, vehicle speed, coolant temperature, and fuel trim levels. This snapshot allows you to reconstruct the scenario when the fault occurred, which can provide clues to the root cause. For example, a freeze frame showing high RPM and heavy throttle might indicate a problem related to high engine load. Looking at how to read scan tool live data can be helpful for understanding freeze frame data. You can check out our guide how to read scan tool live data.

“Freeze frame data is a time machine for diagnostics,” states Maria Sanchez, a leading expert in automotive electronics. “It takes you back to the precise moment the problem occurred, revealing valuable clues that would otherwise be lost.”

Advanced Scan Tool Features and Their Uses

Modern scan tools offer advanced features beyond basic DTC reading and live data. These features include Mode 6 data (on-board diagnostic monitoring test results), bidirectional controls (allowing you to activate certain components through the scan tool), and special functions specific to certain vehicle makes and models.

Leveraging Advanced Scan Tool Functionality

Mode 6 data can provide deeper insights into the performance of various systems and components. Bidirectional controls allow you to test components directly, such as activating fuel injectors or cycling an EGR valve, eliminating guesswork. Familiarizing yourself with these advanced capabilities can significantly enhance your diagnostic abilities. Find more information and discuss your experiences on our scan tool forums.

Conclusion: Mastering Scan Tool Data for Effective Car Repair

Mastering how to read scan tool data is an essential skill for anyone working on today’s vehicles. From interpreting basic DTCs to utilizing advanced features like live data and freeze frame data, this guide has provided you with the foundational knowledge to effectively diagnose car problems. Don’t hesitate to explore our resources on car scanner pro no.plus or.minus.symbol on charts for further assistance. Remember, the more you practice using your scan tool and interpreting the data it provides, the more confident and proficient you will become in diagnosing and repairing vehicles. Connect with ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA, for further assistance or inquiries.