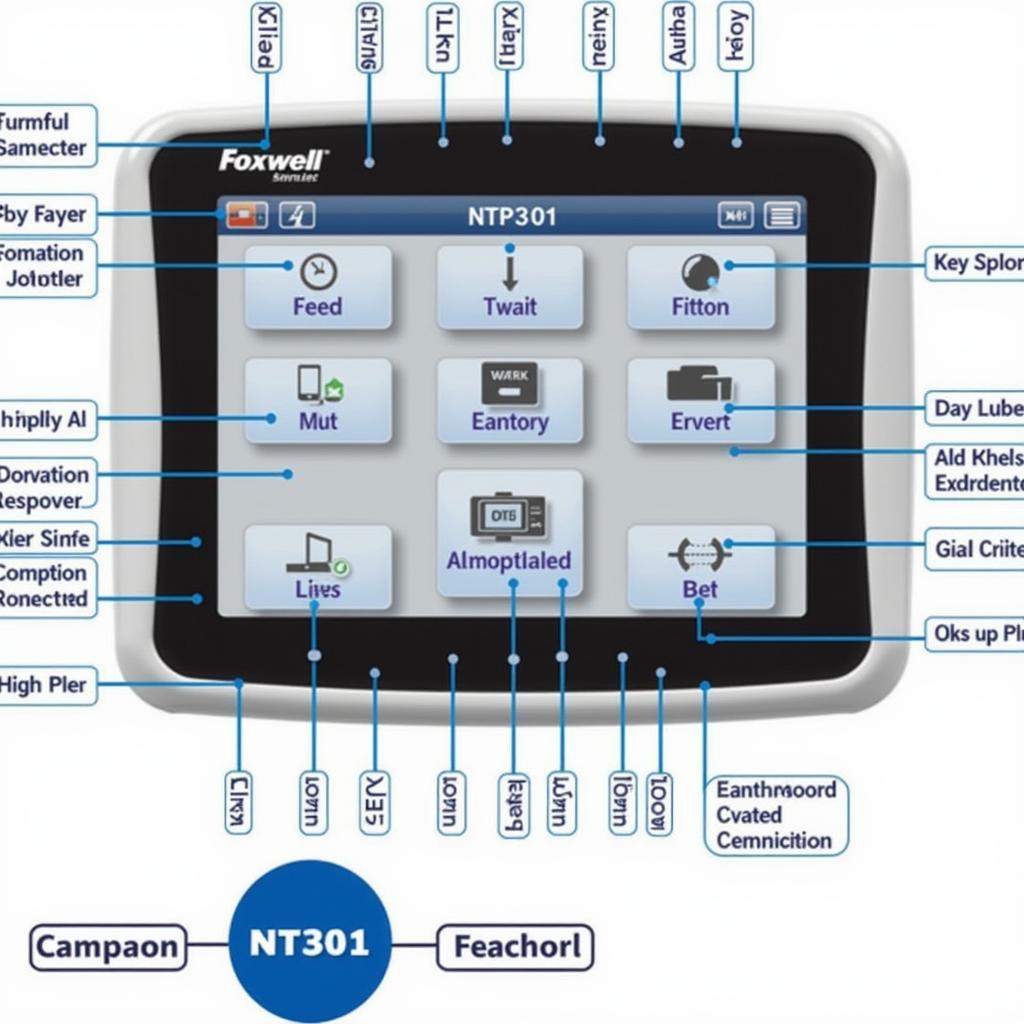

When your car’s check engine light throws you a curveball, the Foxwell NT301 scan tool can be your best friend. This handy device reads and deciphers those cryptic Diagnostic Trouble Codes (DTCs), helping you pinpoint the problem. But that’s not all! The Foxwell NT301 also captures a “freeze frame,” a snapshot of your engine’s sensor readings at the exact moment the issue occurred. These freeze frame data points come with their own set of abbreviations, often leaving users scratching their heads.

This article will demystify common Foxwell Nt301 Freeze Frame Abbreviations, empowering you to understand your vehicle’s health better.

Decoding the Language of Your Engine: Essential Foxwell NT301 Freeze Frame Abbreviations

Think of freeze frame data as your car’s version of a black box. Just like investigators use black box data to understand the events leading up to an airplane incident, mechanics and car enthusiasts can leverage freeze frame data to get to the bottom of engine trouble.

The Foxwell NT301 presents this data using specific abbreviations, each representing a critical engine parameter. Let’s break down some of the most frequently encountered ones:

Engine Speed (RPM)

This abbreviation is pretty straightforward. It indicates the speed at which your engine’s crankshaft was rotating at the time the fault occurred. Higher RPMs, especially when coupled with certain DTCs, might suggest an issue with the ignition system, fuel delivery, or even a mechanical problem.

Calculated Load Value (%)

This value represents how much load the engine was under at the time of the fault. A high load value when the error occurred could point to problems with the airflow sensor, fuel system, or even a restriction in the exhaust system.

Coolant Temperature (ECT)

Knowing your engine’s coolant temperature is crucial. If the ECT is abnormally high when the DTC was triggered, it could indicate a problem with the cooling system, such as a faulty thermostat, a failing water pump, or a coolant leak.

Short Term Fuel Trim (STFT) and Long Term Fuel Trim (LTFT) (%)

These two parameters provide insight into your car’s fuel management system. STFT represents the immediate adjustments the engine control unit (ECU) makes to the fuel-air mixture, while LTFT reflects long-term adjustments. Large variations, either positive or negative, in these trims could indicate issues with the oxygen sensors, fuel injectors, or a vacuum leak.

Intake Air Temperature (IAT)

The IAT sensor measures the temperature of the air entering the engine. The ECU uses this information to optimize the air-fuel mixture for combustion. Unusual IAT readings in the freeze frame data could signal a problem with the sensor itself or an issue with the air intake system.

Manifold Absolute Pressure (MAP)

The MAP sensor plays a vital role in determining the amount of air entering the engine. This data, along with the engine speed, helps the ECU calculate the appropriate amount of fuel to inject. Discrepancies in the MAP reading could indicate a problem with the sensor, a vacuum leak, or issues with the EGR system.

Why Understanding Freeze Frame Data is Crucial

“Freeze frame data provides crucial context to the DTC,” says automotive electronics expert and veteran mechanic, James O’Connell. “It’s like having a witness at the scene of the crime. These snapshots of engine conditions help us recreate the scenario when the problem occurred, leading to faster and more accurate diagnoses.”

Freeze frame data allows you to move beyond simply knowing what’s wrong to understanding why it’s wrong.

For example, if your car throws a code related to a misfire, the freeze frame data can tell you if the misfire happened under high load, low speed, or a specific temperature range. This information can be invaluable in narrowing down the potential causes, saving you time and potentially costly misdiagnoses.

Going Beyond the Basics: Using Freeze Frame Data Effectively

While understanding the common Foxwell NT301 freeze frame abbreviations is a great starting point, there’s a whole world of information hidden within these data points. Here are some tips to unlock its full potential:

- Always Compare: Don’t just look at the freeze frame data in isolation. Compare the values with the expected ranges for your specific vehicle make and model. Your car’s service manual is a treasure trove of this information.

- Look for Patterns: If you’re dealing with intermittent problems, analyze the freeze frame data from multiple instances of the same DTC. Look for patterns or trends in the readings that could provide clues.

- Don’t Ignore the Obvious: While some issues require a deep dive into the data, others might have obvious red flags. If a value is significantly outside the normal range, it’s a good place to start your investigation.

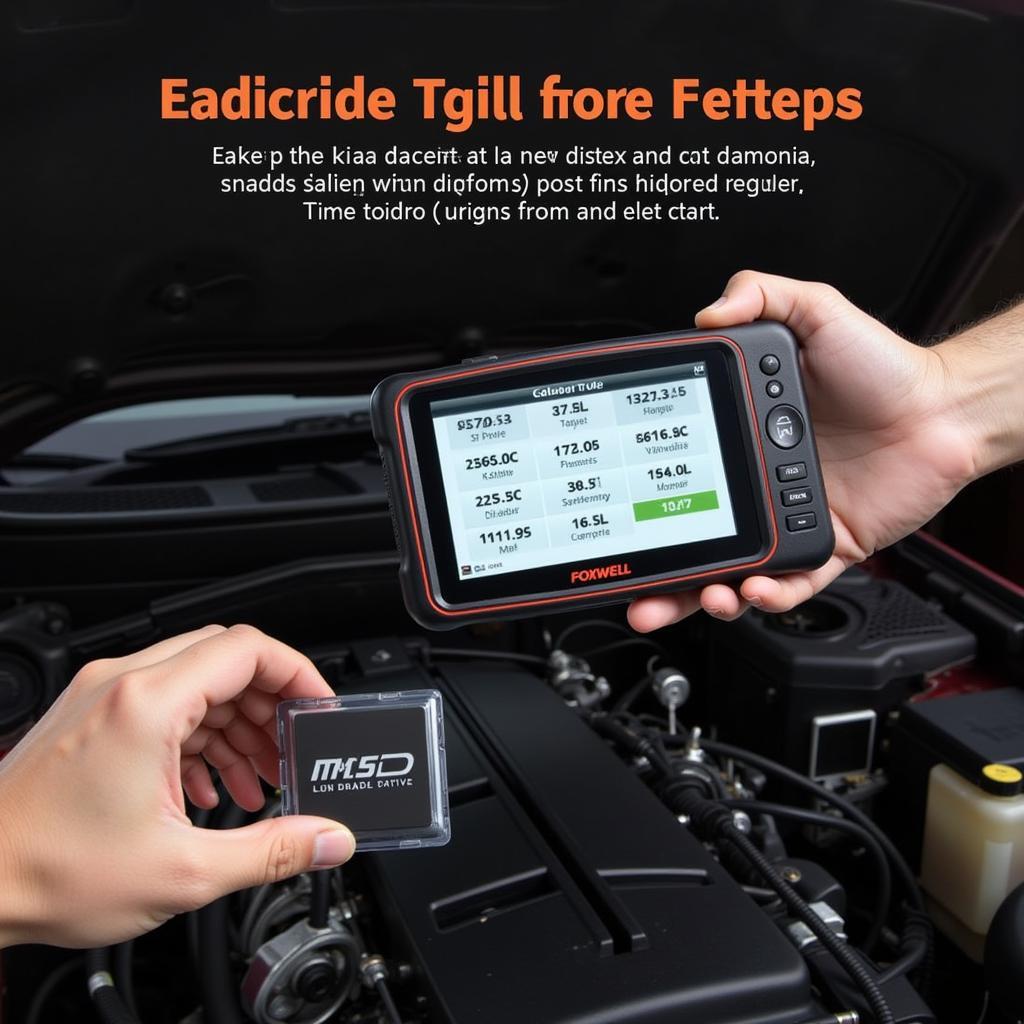

- Use It with Live Data: Combine the insights from freeze frame data with live data streaming from your Foxwell NT301 for a more dynamic understanding of your engine’s behavior.

Foxwell NT301: Your Partner in Automotive Diagnostics

The Foxwell NT301 is more than just a code reader; it’s a powerful diagnostic tool that can empower you to take control of your car’s health. By understanding the language of freeze frame abbreviations, you can gain deeper insights into your engine’s performance and tackle car troubles with confidence.

Need help interpreting your Foxwell NT301 freeze frame data? Don’t hesitate to reach out! Contact ScanToolUS at +1 (641) 206-8880 or visit our office located at 1615 S Laramie Ave, Cicero, IL 60804, USA. We are here to assist you!