The automotive industry is rapidly evolving, with technology playing an increasingly vital role in vehicle diagnostics and repair. For automotive technicians and repair shops, having the right tools and equipment is essential for efficient and accurate service. This article delves into the importance of using a Drb Scan Tool Along With An Approved Gasoline Draining Station, highlighting their benefits, applications, and safety considerations.

Understanding the DRB Scan Tool

A DRB scan tool is a specialized diagnostic tool designed to communicate with a vehicle’s onboard computer system. It retrieves diagnostic trouble codes (DTCs), live data streams, and other crucial information that helps pinpoint the root cause of malfunctions.

Advantages of Using a DRB Scan Tool

- Accurate Diagnosis: DRB scan tools provide precise diagnostic information, reducing guesswork and unnecessary repairs.

- Time Efficiency: By quickly identifying issues, DRB scan tools streamline the repair process, saving time and effort.

- Enhanced Functionality: Beyond basic diagnostics, these tools can perform tasks like module programming, actuator tests, and system resets.

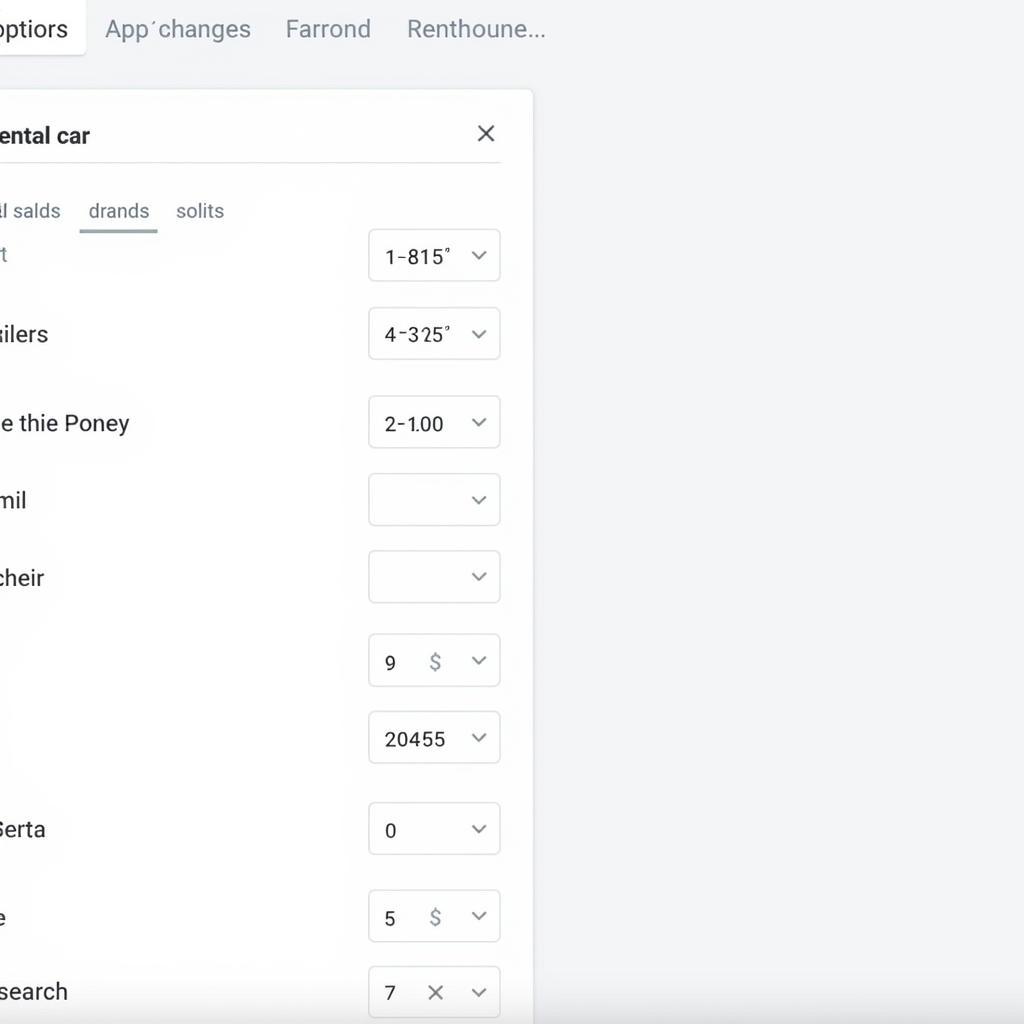

Mechanic using a DRB scan tool to diagnose a car

Mechanic using a DRB scan tool to diagnose a car

The Importance of an Approved Gasoline Draining Station

Working with gasoline requires strict adherence to safety protocols. An approved gasoline draining station provides a safe and controlled environment for removing fuel from vehicles.

Safety and Environmental Benefits:

- Fire Prevention: Gasoline is highly flammable. A dedicated draining station minimizes the risk of fire hazards.

- Vapor Control: These stations are equipped with vapor recovery systems, preventing harmful gasoline fumes from escaping into the atmosphere.

- Spill Containment: In case of accidental spills, the station’s containment system prevents fuel from contaminating the work area or environment.

Synergy of DRB Scan Tools and Draining Stations

While seemingly separate, the use of a DRB scan tool often goes hand-in-hand with the need for a gasoline draining station.

Scenario: Imagine a vehicle displaying engine performance issues. The DRB scan tool identifies a faulty fuel pump or a contaminated fuel system. To repair this, the fuel tank might need to be drained and cleaned, necessitating the use of a gasoline draining station.

“Using a DRB scan tool alongside an approved gasoline draining station allows us to address a wide range of fuel-related issues safely and efficiently,” says John Miller, a senior automotive technician with over 20 years of experience. “The combination is crucial for maintaining a safe work environment and delivering quality repairs.”

A mechanic draining fuel from a car at a designated station

A mechanic draining fuel from a car at a designated station

Choosing the Right Equipment

Selecting the appropriate DRB scan tool and gasoline draining station is paramount for optimal performance and safety.

Factors to Consider:

- Vehicle Compatibility: Ensure the DRB scan tool supports the make, model, and year of the vehicles you service.

- Software Updates: Regular software updates are essential for the scan tool to access the latest vehicle systems and diagnostic information.

- Station Capacity: Choose a gasoline draining station with a capacity suitable for your workshop’s needs.

- Safety Features: Prioritize stations with features like overfill protection, emergency shut-off valves, and explosion-proof components.

Conclusion

The automotive landscape is becoming increasingly complex. As technology advances, having the right tools is no longer just an advantage but a necessity. The DRB scan tool and an approved gasoline draining station are prime examples of tools that enhance both the efficiency and safety of automotive repair. Investing in these tools is an investment in the future of your business and the well-being of your technicians.

For more information on DRB scan tools and approved gasoline draining stations, contact ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA.