Navigating the complexities of heavy machinery maintenance can be daunting, especially when dealing with intricate electronic systems. A Terex diagnostic code tool emerges as an essential tool for both seasoned mechanics and equipment owners looking to decipher and address technical issues in their Terex machines. This comprehensive guide delves into the intricacies of using a diagnostic code tool for Terex equipment, providing valuable insights for efficient troubleshooting and repair.

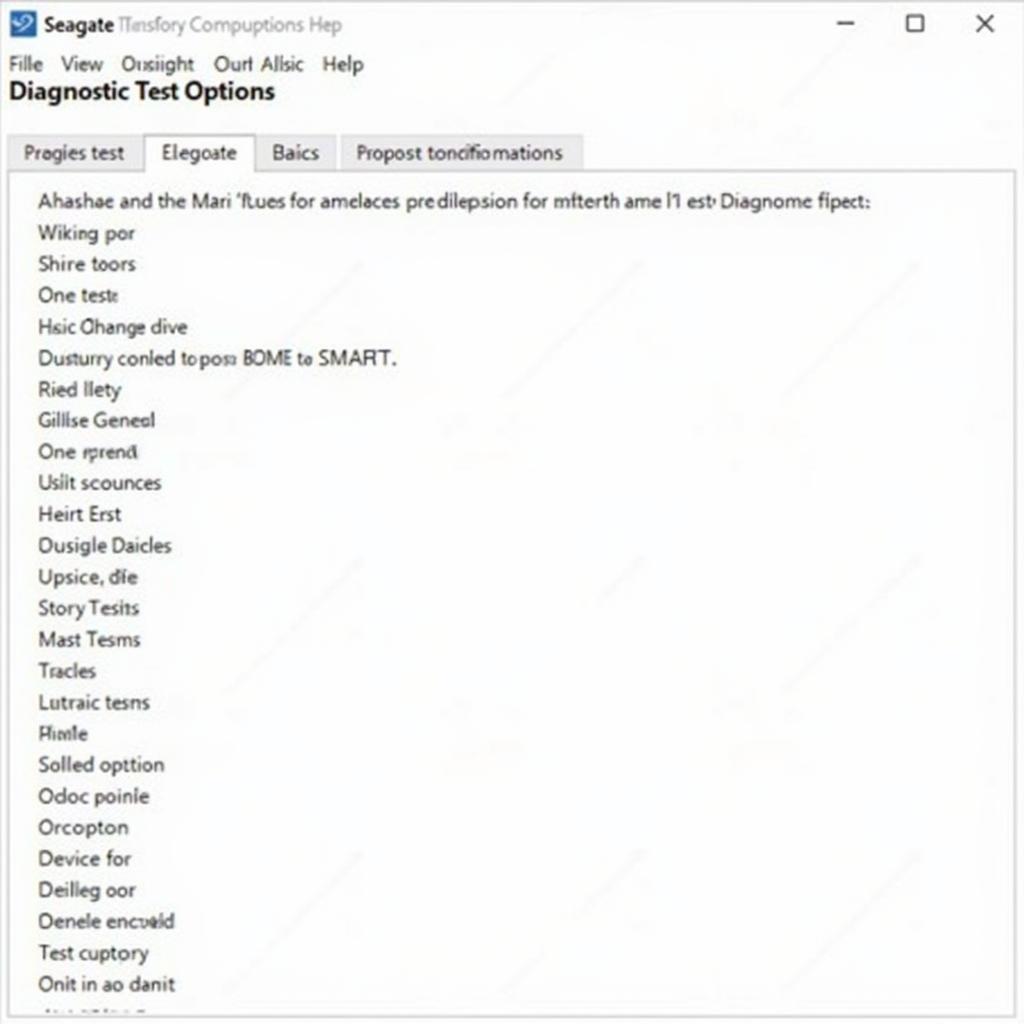

Terex Diagnostic Tool in Action

Terex Diagnostic Tool in Action

Understanding Diagnostic Code Tools: Your Key to Unlocking Equipment Issues

Gone are the days of relying solely on mechanical know-how to diagnose equipment problems. Modern Terex machinery is equipped with sophisticated electronic systems that monitor various aspects of machine performance. When a fault occurs, these systems generate diagnostic trouble codes (DTCs), providing valuable clues about the underlying issue. This is where a Terex diagnostic code tool comes into play.

Think of a diagnostic code tool as a specialized translator for your Terex equipment. It allows you to communicate directly with the machine’s onboard computer, retrieving and interpreting the stored DTCs. This information is crucial for pinpointing the root cause of malfunctions, enabling targeted repairs and minimizing downtime.

Various Terex Diagnostic Tools

Various Terex Diagnostic Tools

Choosing the Right Diagnostic Code Tool for Your Needs

Selecting the appropriate Terex diagnostic code tool is paramount for effective troubleshooting. With a range of options available, it’s essential to consider your specific requirements. Factors to consider include:

- Terex Model Compatibility: Ensure the diagnostic tool is compatible with the specific model year and type of your Terex equipment.

- Functionality: Determine the level of detail and functionality you need. Some tools provide basic code reading capabilities, while others offer advanced features like live data streaming, component activation, and bi-directional control.

- User Interface: Opt for a tool with a user-friendly interface and clear, concise data presentation.

- Budget: Diagnostic tools come in various price ranges, so consider your budget and the tool’s features.

Putting Your Diagnostic Code Tool to Work

Once you’ve chosen the appropriate diagnostic tool, follow these steps to diagnose and troubleshoot issues with your Terex equipment:

-

Safety First: Before connecting the tool, engage the parking brake, turn off the engine, and disconnect the battery’s negative terminal.

-

Locate the Diagnostic Port: Consult your Terex operator’s manual to locate the diagnostic port. It’s typically located under the dashboard or in the engine compartment.

-

Connect the Tool: Connect the diagnostic code tool to the diagnostic port.

-

Turn on the Ignition: Turn the ignition key to the “on” position without starting the engine.

-

Access the DTCs: Follow the tool’s instructions to access the stored DTCs. This may involve navigating through menus or selecting specific options.

-

Record the Codes: Carefully record all displayed DTCs, including any accompanying descriptions or freeze frame data.

-

Interpret the Codes: Use the tool’s built-in code library, online resources, or your Terex service manual to interpret the meaning of each DTC.

-

Diagnose the Problem: Based on the interpreted codes and any additional symptoms, diagnose the root cause of the problem.

-

Perform Repairs: Carry out the necessary repairs based on your diagnosis.

-

Clear the Codes: After completing the repairs, use the diagnostic tool to clear the DTCs.

(https://scantoolus.com/terex-pt-110-diagnostic-tool/) on a piece of Terex equipment, emphasizing its user-friendliness and effectiveness.]

Beyond Code Reading: Leveraging Advanced Features

While reading and interpreting diagnostic codes is a primary function, many diagnostic tools offer advanced features that elevate troubleshooting capabilities. These features include:

- Live Data Streaming: Observe real-time sensor data from various systems, aiding in identifying intermittent issues and monitoring component performance.

- Component Activation: Activate specific components, such as solenoids, actuators, and relays, to test their functionality and isolate faults.

- Bi-Directional Control: Send commands to the vehicle’s electronic control units (ECUs) to test outputs, calibrate sensors, and perform advanced diagnostics.

Conclusion: Empowering Maintenance and Minimizing Downtime

Investing in a Terex diagnostic code tool is a strategic decision for equipment owners and technicians alike. By providing access to critical diagnostic information, these tools empower users to take charge of maintenance, identify issues proactively, and minimize costly downtime. Whether you’re troubleshooting engine problems, hydraulic malfunctions, or electrical gremlins, a diagnostic code tool serves as your indispensable companion in keeping your Terex equipment running smoothly.

Need assistance selecting the right diagnostic code tool for your Terex equipment? Contact the experts at ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA. We’re here to help you find the perfect tool for your needs.