A failing crankshaft position sensor can cause a variety of drivability issues, from hard starting to stalling. Replacing the sensor is often the first step, but sometimes a Crank Sensor Relearn Scan Tool is necessary to complete the repair. This guide will explore everything you need to know about crank sensor relearn procedures, the tools involved, and how to choose the right one for your needs.

After replacing a faulty crankshaft position sensor, some vehicles require a relearn procedure to be performed. This allows the engine control module (ECM) to recognize the new sensor and function correctly. For many vehicles, this involves using a crank sensor relearn scan tool. You can find more information about this topic on our page about crank sensor relearn scan tool cts.

What is a Crank Sensor Relearn Procedure?

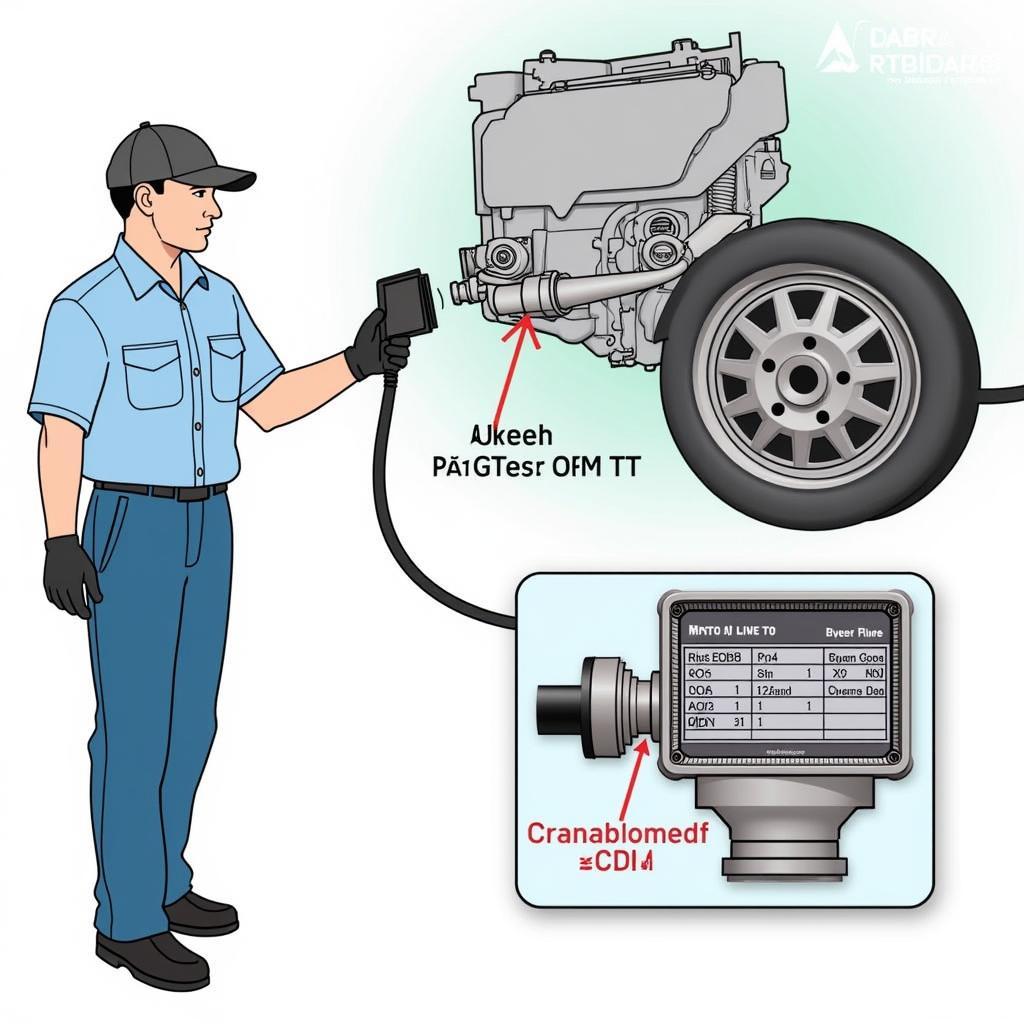

The crank sensor relearn procedure is a vital step in certain vehicle repairs after replacing the crankshaft position sensor. The procedure involves using a scan tool to communicate with the vehicle’s ECM and input the new sensor’s information. This process synchronizes the new sensor with the ECM, allowing the engine to operate correctly. The specific steps involved can vary depending on the make and model of the vehicle.

Crank Sensor Relearn Procedure Illustration

Crank Sensor Relearn Procedure Illustration

Why Do Some Vehicles Require a Crank Sensor Relearn?

Modern vehicles rely heavily on electronic control systems to manage engine functions. The crankshaft position sensor provides crucial information to the ECM, which uses this data for vital tasks like fuel injection timing and ignition control. When a sensor is replaced, the ECM sometimes needs to be “reintroduced” to the new sensor to ensure proper synchronization and prevent performance issues.

Choosing the Right Crank Sensor Relearn Scan Tool

Selecting the appropriate crank sensor relearn scan tool is essential for a successful repair. Several factors should be considered:

- Vehicle Compatibility: Ensure the scan tool is compatible with the make, model, and year of the vehicle being worked on.

- Functionality: Verify the scan tool can perform the specific relearn procedure required for the vehicle. Some tools offer a wider range of functionalities beyond just crank sensor relearn.

- User-Friendliness: Choose a scan tool with an intuitive interface and easy-to-navigate menus. This can save valuable time and prevent frustration during the relearn process. You can find some highly rated scan tools on our best rated automotive scan tool page.

- Cost: Scan tools range in price from budget-friendly options to high-end professional models. Consider your budget and the frequency with which you’ll be performing these procedures. If you are looking for a more affordable option, check out our page about crank sensor relearn scan tool harbor freight.

Different Types of Crank Sensor Relearn Scan Tools

Different Types of Crank Sensor Relearn Scan Tools

Performing the Crank Sensor Relearn Procedure

While the specific steps vary depending on the vehicle, the general process typically involves connecting the scan tool to the vehicle’s OBD-II port, selecting the appropriate relearn function, and following the on-screen prompts. It’s crucial to consult the vehicle’s service manual for precise instructions.

Can You Relearn a Crank Sensor Without a Scan Tool?

In some cases, it may be possible to relearn a crank sensor without a scan tool. This often involves a specific driving cycle or a series of key-on/key-off sequences. However, this method is not always reliable and may not work on all vehicles. For more details on this, visit our page on how to relearn crankshaft position sensor without scan tool. Using a scan tool is generally recommended for the most accurate and efficient relearn procedure.

Case Relearn Scan Tool: A Specific Example

For vehicles requiring a CASE (Crankshaft Angle Sensor Error) relearn, a dedicated case relearn scan tool may be necessary. These tools are designed specifically for this procedure and can streamline the process. You can find more information about case relearn scan tools on our case relearn scan tool page.

Quote from John Smith, Senior Automotive Technician at ABC Auto Repair: “Using the right scan tool for a crank sensor relearn can save you hours of diagnostic time and prevent misdiagnosis. It’s an investment that pays for itself in the long run.”

Conclusion

A crank sensor relearn scan tool is an invaluable tool for anyone working on modern vehicles. Understanding its function and choosing the right tool can greatly simplify the repair process and ensure the vehicle runs smoothly after a crankshaft position sensor replacement. Remember to always consult the vehicle’s service manual for specific instructions. If you have any questions or need assistance with choosing the right crank sensor relearn scan tool, feel free to reach out to us. We’re here to help!

Quote from Maria Garcia, Certified Automotive Instructor: “Investing in a quality crank sensor relearn scan tool not only makes your job easier but also shows your commitment to providing professional and reliable service to your customers.”

Contact us at ScanToolUS: +1 (641) 206-8880. Our office is located at 1615 S Laramie Ave, Cicero, IL 60804, USA.