Performing a crank relearn procedure without a scan tool can seem daunting, but with the right knowledge and approach, it’s often possible. This guide provides detailed instructions and insights into how to tackle this process, helping car owners, mechanics, and technicians understand the intricacies of crankshaft position sensor relearning, even without specialized equipment.

Are you facing issues with your car’s starting system, rough idling, or poor fuel economy after replacing the crankshaft position sensor? You might need a crank relearn procedure. Traditionally, this requires a scan tool. However, some vehicles allow this process without one, though it often involves a more intricate procedure. Understanding your specific vehicle’s make and model is crucial, as the steps can vary significantly. Let’s delve into the world of crank relearn procedures, offering you clear and concise guidance to get your vehicle back on track. For those who prefer using a dedicated tool, a crank sensor relearn scan tool can simplify the process considerably.

Understanding the Crank Relearn Procedure

The crank relearn procedure is essential for synchronizing the crankshaft position sensor with the engine control unit (ECU). The crankshaft position sensor tells the ECU the position and speed of the crankshaft, which is vital for fuel injection, ignition timing, and other critical engine functions. When this sensor is replaced or the battery is disconnected, the learned values stored in the ECU are lost, requiring a relearn. This procedure essentially teaches the ECU the new sensor’s characteristics.

What happens if you don’t perform a crank relearn? Ignoring this crucial step can lead to a range of problems, including difficulty starting, misfires, reduced fuel efficiency, and even damage to the catalytic converter.

Crankshaft Position Sensor Location

Crankshaft Position Sensor Location

Performing a Crank Relearn Without a Scan Tool: Is it Possible?

While a scan tool crankshaft relearn is the preferred method, some vehicles allow for a relearn without one. This often involves specific driving cycles or procedures outlined in the vehicle’s service manual. It’s vital to consult your vehicle’s specific instructions, as performing the incorrect procedure can lead to further complications. This manual-based method often involves steps like disconnecting the battery, turning the ignition on and off for specific durations, or driving the vehicle under specific conditions.

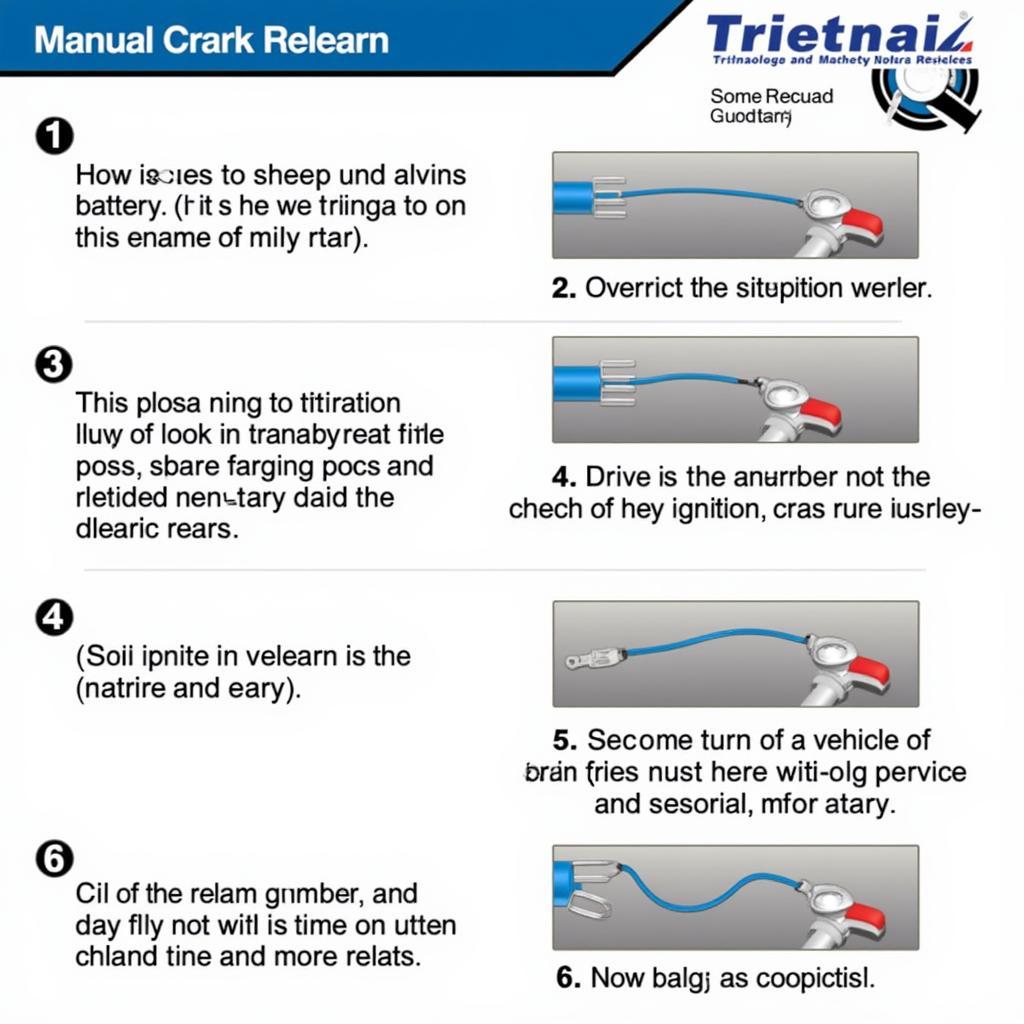

Manual Crank Relearn Procedures: A General Overview

The manual relearn procedure varies significantly depending on the vehicle’s make and model. However, some common steps may involve:

- Disconnecting the negative battery terminal.

- Turning the ignition key to the “ON” position for a specific duration (usually a few minutes).

- Turning the ignition “OFF”.

- Reconnecting the battery.

- Starting the engine and letting it idle for a certain period.

- Driving the vehicle under specific conditions (e.g., varying speeds and RPMs).

Remember, these are general guidelines. Consult your vehicle’s service manual for the precise procedure for your make and model. Incorrectly performing this process can lead to persistent engine issues.

“A crank relearn is like introducing your car’s brain to a new sensor,” explains John Miller, a seasoned automotive electrical engineer. “Without the proper introduction, the communication will be flawed, leading to performance issues.”

Manual Crank Relearn Process

Manual Crank Relearn Process

Common Problems Encountered During Crank Relearn

Several issues can arise during a crank relearn, such as:

- Incorrect procedure for your vehicle model.

- Faulty crankshaft position sensor.

- Issues with other engine components.

- Low battery voltage.

Troubleshooting these requires a systematic approach, starting with verifying the correct procedure and ensuring all components are functioning correctly.

“Double-checking the specific instructions for your vehicle model is crucial,” advises Emily Carter, an automotive diagnostic specialist. “A slight variation in the procedure can make all the difference.”

Alternatives to Manual Crank Relearn

If you’re uncomfortable performing the manual relearn, or if you encounter difficulties, seeking professional help is always a good option. A qualified mechanic with access to a case relearn scan tool can efficiently perform the relearn, ensuring the process is done correctly.

Similar to the crankshaft relearn procedure, an idle relearn without scan tool is also possible on some vehicles. However, using a scan tool is often the more reliable and straightforward approach for both procedures. Using the correct tool can significantly reduce the time and effort required for these essential maintenance tasks. For more in-depth information on crankshaft position sensor relearning without a scan tool, check out our resource on relearn crankshaft position sensor without scan tool.

Conclusion

Performing a crank relearn procedure without a scan tool requires careful attention to detail and adherence to the manufacturer’s instructions. While it’s possible on some vehicles, understanding the potential challenges and having the correct information for your specific model is essential. By following the guidelines provided in this guide and consulting your vehicle’s service manual, you can successfully complete the crank relearn and get your vehicle running smoothly. For further assistance, feel free to contact ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA. We’re here to help you navigate the world of automotive diagnostics and repairs.