Nội dung bài viết

- Understanding the Importance of Chrysler Diagnostic Engineering Tools

- Why Choose a Chrysler-Specific Diagnostic Tool?

- Types of Chrysler Diagnostic Engineering Tools

- Choosing the Right Tool for Your Needs

- Using a Chrysler Diagnostic Engineering Tool: A Step-by-Step Guide

- Advanced Features of Chrysler Diagnostic Engineering Tools

- Conclusion

- FAQ

A Chrysler Diagnostic Engineering Tool is essential for efficiently diagnosing and resolving vehicle issues. Whether you’re a seasoned mechanic or a car enthusiast, understanding these powerful tools can save you time and money. This guide delves into the world of Chrysler diagnostic tools, providing valuable insights for both professionals and DIYers.

Understanding the Importance of Chrysler Diagnostic Engineering Tools

Modern Chrysler vehicles are complex systems of interconnected electronic components. When a problem arises, pinpointing the root cause can be challenging without the right equipment. This is where Chrysler diagnostic engineering tools come into play. These specialized tools, ranging from handheld scanners to sophisticated software suites, allow technicians to communicate with the vehicle’s onboard computer system, retrieve diagnostic trouble codes (DTCs), and access live data streams.

Why Choose a Chrysler-Specific Diagnostic Tool?

While generic OBD-II scanners can read basic codes, a dedicated Chrysler diagnostic engineering tool offers more in-depth functionality. They provide access to manufacturer-specific codes, bi-directional controls, and advanced features like module programming and key fob registration. This level of detail is crucial for accurately diagnosing and resolving complex issues within Chrysler’s intricate electronic systems.

Chrysler Diagnostic Tool in Action

Chrysler Diagnostic Tool in Action

Types of Chrysler Diagnostic Engineering Tools

The market offers a wide variety of Chrysler diagnostic engineering tools, each tailored to different needs and budgets. Here’s a breakdown of common types:

- Handheld Scanners: Portable and affordable, these devices are ideal for quick code retrieval and basic diagnostics.

- PC-Based Software: Offering greater functionality than handheld scanners, PC-based software provides access to more advanced features like bi-directional controls and module programming. This software often requires a separate interface device to connect to the vehicle.

- OEM-Level Tools: These are the most comprehensive diagnostic engineering tools available, offering the full range of diagnostic and programming capabilities utilized by Chrysler dealerships. These tools come with a premium price tag but provide unparalleled access to the vehicle’s systems.

Choosing the Right Tool for Your Needs

Selecting the appropriate Chrysler diagnostic engineering tool depends on your specific requirements. Consider factors such as your budget, the level of diagnostic functionality you need, and the types of vehicles you work on.

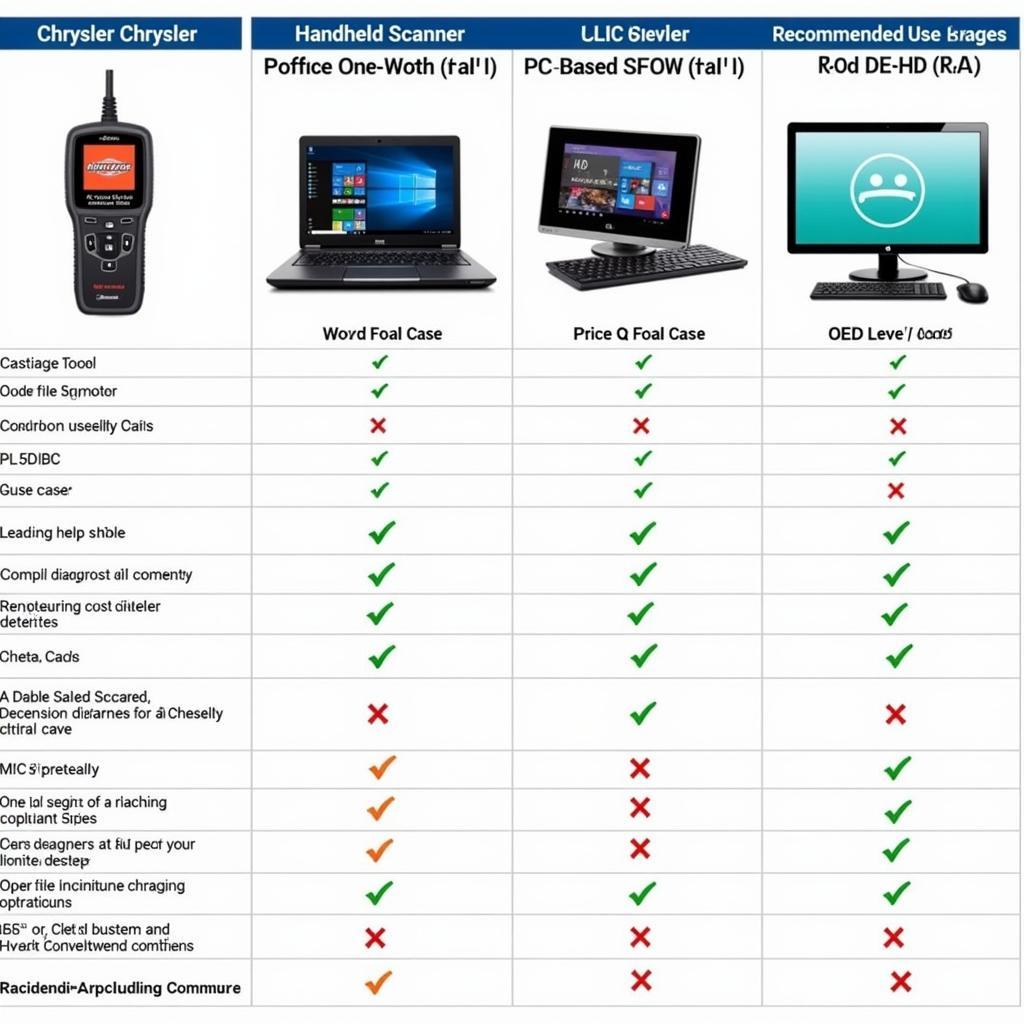

Comparing Different Chrysler Diagnostic Tools

Comparing Different Chrysler Diagnostic Tools

Using a Chrysler Diagnostic Engineering Tool: A Step-by-Step Guide

Let’s walk through the basic steps of using a Chrysler diagnostic engineering tool:

- Connect the Tool: Locate the OBD-II port on your Chrysler vehicle (usually located under the dashboard on the driver’s side). Connect the diagnostic tool to the port.

- Turn on the Ignition: Turn the ignition key to the “on” position without starting the engine.

- Power on the Tool: Turn on the diagnostic tool and follow the on-screen prompts.

- Retrieve Diagnostic Trouble Codes (DTCs): Select the option to read DTCs. The tool will scan the vehicle’s computer system and display any stored codes.

- Interpret DTCs: Use a reliable resource to look up the meaning of the retrieved DTCs. This will help you understand the nature of the problem.

- Clear DTCs: Once the issue has been addressed, you can use the tool to clear the stored codes.

“Regularly scanning your Chrysler with the appropriate diagnostic tool is a proactive approach to vehicle maintenance,” advises John Miller, a veteran automotive engineer with over 20 years of experience. “Early detection of potential issues can prevent minor problems from escalating into major repairs.”

Mechanic Interpreting DTCs on Chrysler Diagnostic Tool

Mechanic Interpreting DTCs on Chrysler Diagnostic Tool

Advanced Features of Chrysler Diagnostic Engineering Tools

Beyond basic code retrieval, Chrysler diagnostic engineering tools often provide advanced functionalities:

- Live Data Streaming: Observe real-time data from various sensors, providing valuable insights into the vehicle’s operation.

- Bi-Directional Controls: Test components by activating them directly through the diagnostic tool.

- Module Programming: Update and reprogram control modules within the vehicle.

- Key Fob Registration: Program new key fobs to the vehicle’s security system.

“The ability to access live data and perform bi-directional controls is invaluable for diagnosing intermittent problems,” adds Sarah Chen, a certified Chrysler technician. “These features allow us to pinpoint issues that might not be evident from DTCs alone.”

Conclusion

Mastering the use of a Chrysler diagnostic engineering tool is a crucial skill for anyone involved in maintaining or repairing these vehicles. These powerful tools provide essential insights into the complex electronic systems that govern modern Chrysler vehicles, enabling efficient diagnosis and effective repairs. Whether you’re a professional technician or a dedicated car enthusiast, choosing the right Chrysler diagnostic engineering tool will empower you to tackle automotive challenges with confidence. Contact ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA, for expert advice and a wide selection of Chrysler diagnostic tools.

FAQ

-

What is a Chrysler diagnostic engineering tool? A specialized tool used to communicate with a Chrysler’s computer system, retrieve diagnostic information, and perform advanced functions like module programming.

-

Why do I need a Chrysler-specific tool? Generic OBD-II scanners offer limited functionality. Chrysler-specific tools provide access to manufacturer-specific codes and advanced features.

-

How do I use a Chrysler diagnostic engineering tool? Connect the tool to the OBD-II port, turn on the ignition, power on the tool, retrieve and interpret DTCs, and clear codes once the issue is resolved.

-

What are some advanced features of these tools? Live data streaming, bi-directional controls, module programming, and key fob registration are some examples.

-

Where can I purchase a Chrysler diagnostic engineering tool? Reputable automotive tool suppliers and online retailers offer a variety of options.

-

How do I choose the right tool for my needs? Consider your budget, required functionality, and the types of vehicles you work on.

-

Can I use a Chrysler diagnostic engineering tool on other car brands? While some tools may offer limited compatibility, using a Chrysler-specific tool on other brands is generally not recommended.