Chelsea Foxwell, a name often whispered in hushed tones amongst automotive electrical technicians, isn’t some mythical figure. It’s a term synonymous with a specific type of advanced electrical connector system found in many modern vehicles. For both seasoned mechanics and everyday car owners, understanding the complexities of this system can mean the difference between a quick fix and a costly headache. This guide delves into the intricacies of Chelsea Foxwell connectors, equipping you with the knowledge to troubleshoot and conquer even the most perplexing electrical issues.

What Makes Chelsea Foxwell Connectors Unique?

Unlike traditional automotive wiring harnesses, Chelsea Foxwell systems utilize a modular design. Imagine building blocks, each with its own specific function and connector type. These blocks, often color-coded for easy identification, can be easily added or removed, allowing for greater flexibility in vehicle design and assembly.

However, this modularity also presents unique challenges. Misconnections, damaged pins, and corrosion within the connectors themselves can lead to a cascade of electrical gremlins that can be difficult to diagnose without the right knowledge and tools.

Common Issues and Troubleshooting Tips

Navigating the labyrinthine world of Chelsea Foxwell systems might seem daunting, but a systematic approach can demystify the process:

-

Identify the Problem: Is it a faulty sensor? A malfunctioning actuator? Pinpointing the problematic system is the first step. Modern vehicles rely heavily on onboard diagnostics (OBD-II) systems. Using a compatible OBD-II scanner can reveal valuable diagnostic trouble codes (DTCs) that point toward the source of the issue.

-

Consult Technical Data: Once you’ve got a DTC or a general idea of the affected system, consult the vehicle’s wiring diagrams. These diagrams, often specific to the make, model, and year of the vehicle, provide a roadmap of the Chelsea Foxwell system, detailing connector locations, pin assignments, and wire colors.

Automotive Wiring Diagram for Chelsea Foxwell System

Automotive Wiring Diagram for Chelsea Foxwell System

-

Inspect the Connectors: Visually inspect the suspected connectors for any signs of damage, such as bent or broken pins, loose connections, or corrosion. Remember those color-coded blocks? They are your allies. Ensure the connectors are correctly mated and securely fastened.

-

Test for Continuity and Resistance: A digital multimeter becomes your trusted sidekick at this stage. Use it to check for continuity in the wiring and measure resistance across various points to identify open circuits, shorts, or high resistance connections.

-

Specialized Tools for the Modern Mechanic: For intricate repairs or dealing with particularly stubborn connectors, specialized tools designed explicitly for Chelsea Foxwell systems are invaluable. These tools aid in releasing locking tabs, extracting pins, and ensuring a secure connection during reassembly.

The Importance of Proper Training

“In the world of automotive electrical systems, knowledge truly is power,” says John Miller, a veteran automotive electrical specialist with over 20 years of experience. “Understanding the nuances of Chelsea Foxwell connectors, paired with the right tools and diagnostic approach, is crucial for any technician looking to excel in this field.”

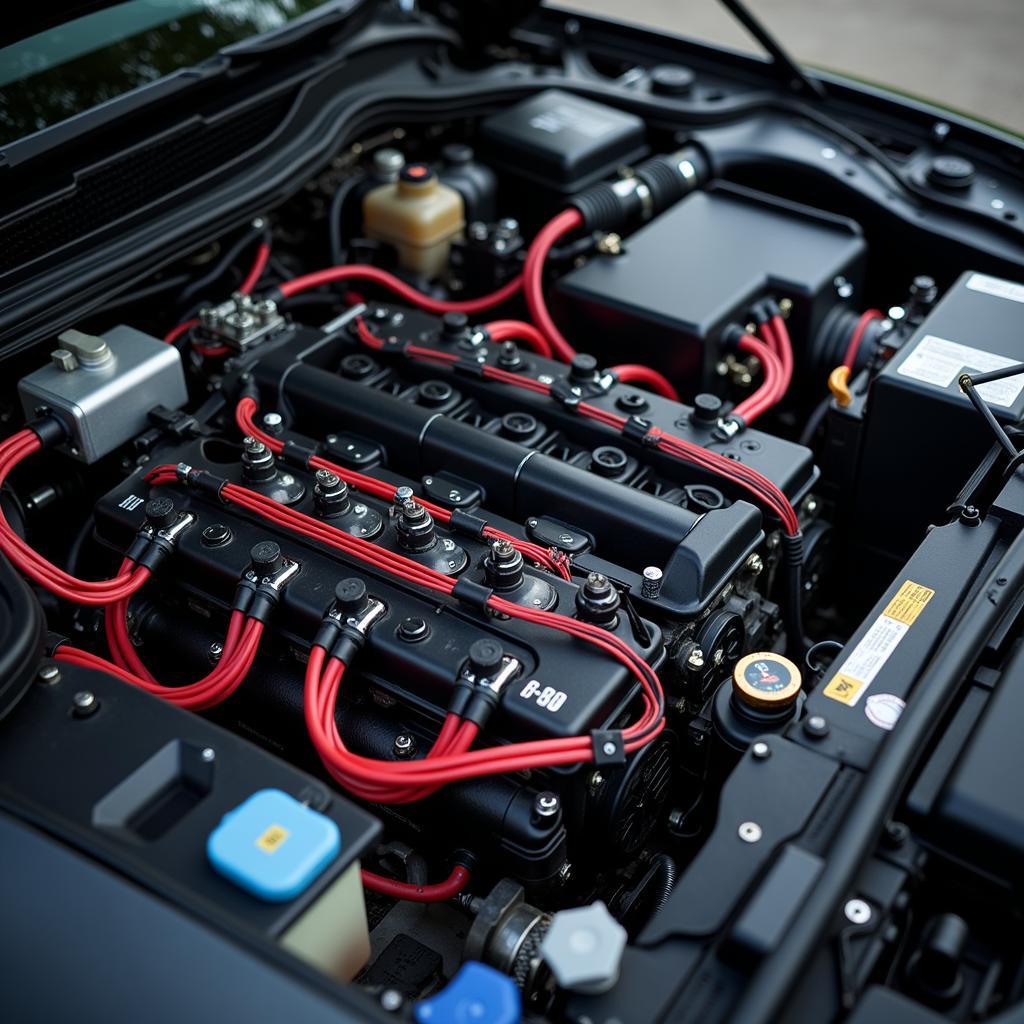

Technician Diagnosing a Chelsea Foxwell Connector

Technician Diagnosing a Chelsea Foxwell Connector

The complexity of modern vehicles necessitates continuous learning. Attending specialized training courses focused on Chelsea Foxwell systems can provide technicians with invaluable hands-on experience and insights into the latest diagnostic and repair techniques.

Chelsea Foxwell: The Future of Automotive Wiring

As vehicles become increasingly sophisticated, Chelsea Foxwell connectors and similar modular systems will likely become the industry standard. Their flexibility, ease of assembly, and potential for incorporating future technological advancements make them a natural fit for the evolution of automotive electrical systems.

Conclusion

Mastering the art of diagnosing and repairing Chelsea Foxwell systems is essential for any automotive professional or enthusiast. By understanding their unique characteristics, utilizing the correct diagnostic procedures, and leveraging specialized tools, you can confidently tackle even the most challenging electrical issues. Remember, a systematic approach, coupled with the right knowledge, can transform a seemingly insurmountable problem into a manageable task.

If you’re facing persistent electrical issues or need expert assistance, don’t hesitate to contact ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA. Our team of skilled technicians is equipped to handle all your automotive electrical needs.

FAQs

1. Are Chelsea Foxwell connectors universal?

No, they are not universal. While the general principles might be similar, different car manufacturers may utilize variations in connector design, pin configurations, and color-coding. Always refer to the vehicle-specific wiring diagrams.

2. Can I repair a damaged Chelsea Foxwell connector myself?

While minor repairs like cleaning corroded pins might be possible, it’s generally recommended to seek professional help for significant damage. Improper repairs can lead to further electrical problems.

3. What are the signs of a faulty Chelsea Foxwell connector?

Intermittent electrical issues, warning lights on the dashboard, malfunctioning sensors or actuators, and communication errors with diagnostic tools are some potential indicators.

4. Where can I find reliable wiring diagrams for my vehicle?

Vehicle manufacturers often provide access to official service information, including wiring diagrams, through online subscription services. You can also find reputable aftermarket sources for such information.

5. What kind of specialized tools are available for working with Chelsea Foxwell connectors?

Various tools are available, including pin extractors, terminal release tools, connector position assurance (CPA) tools, and specialized test probes designed to interface with the connectors.