The lifeblood of many industries, heavy equipment, requires regular maintenance and timely repairs to keep operations running smoothly. Downtime can be costly, which is where a Heavy Equipment Diagnostic Tool comes in. This guide explores the importance of these tools, their functionalities, and how they can save you time and money.

Heavy equipment diagnostic tool in action

Heavy equipment diagnostic tool in action

Why is a Heavy Equipment Diagnostic Tool Essential?

Modern heavy equipment relies heavily on electronic control units (ECUs) to manage various systems, from the engine and transmission to hydraulics and emissions. These ECUs generate a wealth of data, and a diagnostic tool acts as the key to unlocking this information.

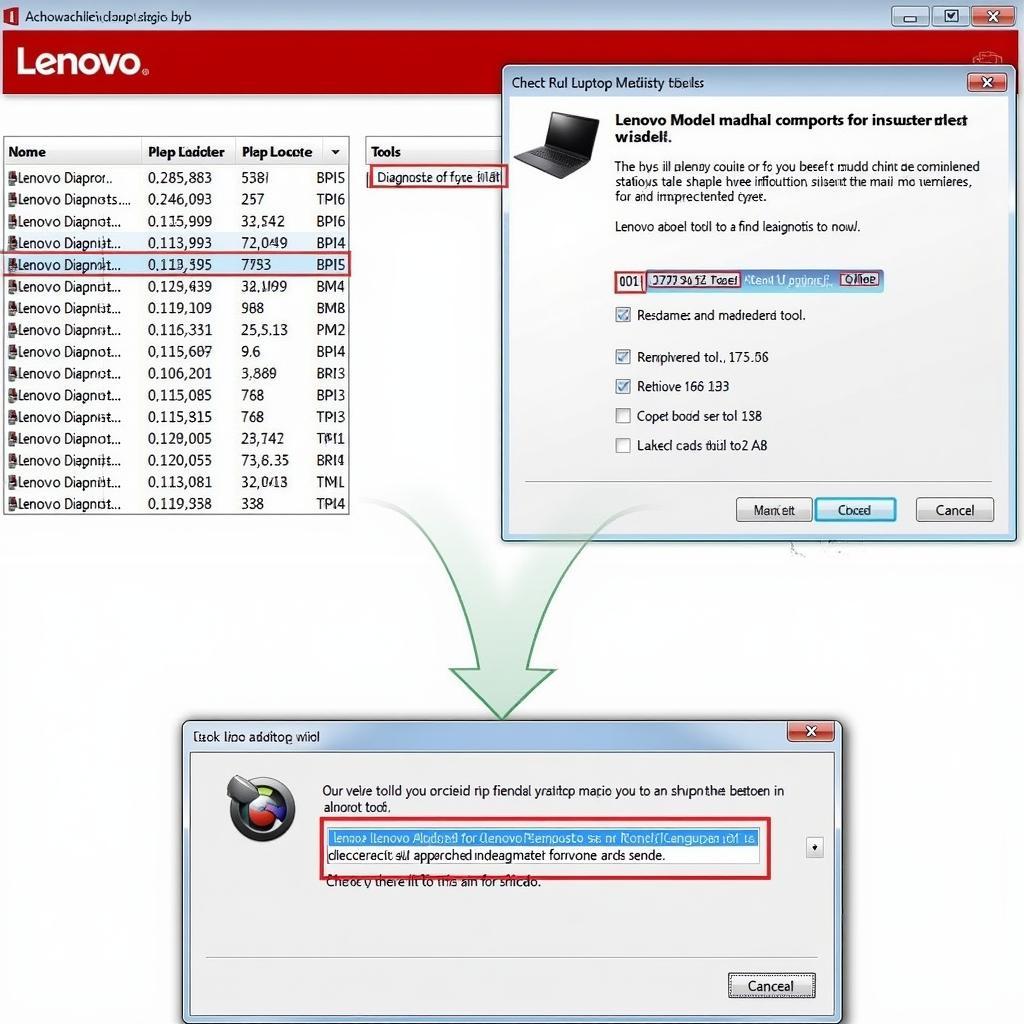

A heavy equipment diagnostic tool, like the scania vci3 diagnostic tool, allows you to:

- Retrieve Diagnostic Trouble Codes (DTCs): These codes pinpoint the specific area where a fault is detected, saving you from time-consuming guesswork.

- Read and Analyze Live Data Streams: Monitor real-time sensor readings to understand how different systems are performing and identify any anomalies.

- Perform Actuator Tests: Activate components like solenoids and valves to verify their functionality and diagnose issues within specific systems.

- Calibrate and Program Modules: Configure new parts, adjust settings, and ensure all systems function optimally after repairs.

- Access Repair Information: Some advanced tools provide direct access to manufacturer databases, offering wiring diagrams, component locations, and troubleshooting guides.

Benefits of Using a Heavy Equipment Diagnostic Tool

The advantages of utilizing a heavy equipment diagnostic tool extend beyond just identifying problems:

- Reduced Downtime: Faster diagnosis translates to quicker repairs, minimizing costly downtime and keeping projects on schedule.

- Accurate Diagnostics: Eliminate guesswork and ensure that the correct repairs are performed the first time, saving on labor and replacement part costs.

- Preventive Maintenance: Regular diagnostics can identify minor issues before they escalate into major problems, preventing unexpected breakdowns and costly repairs.

- Increased Equipment Lifespan: Proper maintenance through timely diagnostics ensures optimal performance and extends the working life of your valuable equipment.

“Investing in a reliable heavy equipment diagnostic tool is like investing in a crystal ball for your fleet,” says John Miller, a veteran heavy equipment mechanic with over 20 years of experience. “It gives you the power to see potential issues before they become major headaches, saving you significant time and money in the long run.”

Choosing the Right Heavy Equipment Diagnostic Tool

The market offers a wide range of diagnostic tools, each with its own set of features and capabilities. Here’s what to consider when choosing the best fit for your needs:

- Equipment Compatibility: Ensure the tool supports the makes and models of equipment in your fleet. Some tools are brand-specific, while others offer multi-brand coverage.

- Functionality: Determine the specific tasks you need the tool to perform. Do you require basic code reading, or are you looking for advanced programming and calibration functionalities?

- Software Updates: Regular software updates are crucial for compatibility with newer equipment models and to access the latest features. Consider tools with affordable or free update options.

- User-Friendliness: Opt for a tool with an intuitive interface, clear navigation, and easy-to-understand data display. Consider factors like screen size, button layout, and overall design.

- Durability and Portability: Since the tool will be used in demanding environments, ensure it is robust, weather-resistant, and portable enough to carry around the workshop or job site.

Popular Heavy Equipment Diagnostic Tools

Several reputable brands and models have gained popularity in the industry:

- JCB Diagnostic Tool: Specifically designed for JCB machinery, offering comprehensive diagnostics and programming capabilities.

- Trend Case Diagnostic Tool: Provides extensive coverage for Case IH and New Holland agricultural and construction equipment.

- Diagnostic Tools for Semi Trucks: Catered to the specific needs of heavy-duty trucks, offering diagnostics for engine, transmission, braking, and other vital systems.

- Diagnostic Code Tool Terex: Specializes in diagnostics and programming for Terex construction and mining equipment.

Conclusion

In an industry where time equals money, a heavy equipment diagnostic tool is no longer a luxury but a necessity. These tools empower owners, mechanics, and fleet managers with the knowledge and capabilities to keep their equipment running at peak performance. By investing in the right diagnostic tool, you invest in the efficiency, longevity, and profitability of your operations.

Need help choosing the best heavy equipment diagnostic tool for your needs? Contact ScanToolUS today at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA. Our team of experts can guide you through the available options and help you make an informed decision.