Testing oxygen sensors is crucial for maintaining optimal engine performance and fuel efficiency. A faulty oxygen sensor can lead to increased emissions, reduced fuel economy, and even engine damage. Foxwell scanners offer a convenient and effective way to diagnose oxygen sensor issues. This comprehensive guide will walk you through the process of testing oxygen sensors using Foxwell scanners, empowering you with the knowledge to troubleshoot and resolve common problems.

Understanding Oxygen Sensors and Their Importance

Oxygen sensors, also known as O2 sensors, are essential components of your vehicle’s emission control system. Located in the exhaust manifold or exhaust pipe, these sensors measure the oxygen content in the exhaust gases. This information is then sent to the engine control unit (ECU), which adjusts the air-fuel mixture accordingly.

A properly functioning oxygen sensor ensures the engine runs at the optimal air-fuel ratio, typically around 14.7:1 for gasoline engines. This ideal ratio maximizes fuel combustion, reduces emissions, and optimizes engine performance.

When to Test Oxygen Sensors

There are several signs that may indicate a failing oxygen sensor, including:

- Check Engine Light Illumination: One of the most common indicators of an oxygen sensor problem is the illumination of the check engine light on your dashboard.

- Decreased Fuel Economy: A faulty oxygen sensor can disrupt the air-fuel mixture, leading to reduced fuel efficiency.

- Rough Engine Idling: If you notice your engine idling roughly or inconsistently, a malfunctioning oxygen sensor could be the culprit.

- Increased Emissions: A failing oxygen sensor can result in increased tailpipe emissions, negatively impacting air quality.

Why Choose Foxwell Scanners for Oxygen Sensor Testing

Foxwell scanners are renowned for their diagnostic capabilities, providing a user-friendly interface and comprehensive functionality for testing oxygen sensors. Here are some compelling reasons to choose Foxwell scanners:

- Wide Vehicle Coverage: Foxwell scanners are compatible with a wide range of vehicle makes and models, ensuring compatibility with your specific car.

- Advanced Diagnostic Features: These scanners offer advanced diagnostic capabilities, allowing you to access and analyze oxygen sensor data with ease.

- Real-Time Data Display: Foxwell scanners provide real-time data streams, enabling you to monitor oxygen sensor readings in real-time and identify any abnormalities.

- Cost-Effective Solution: Compared to expensive dealership visits, Foxwell scanners offer a cost-effective solution for diagnosing and troubleshooting oxygen sensor issues yourself.

Step-by-Step Guide to Testing Oxygen Sensors with Foxwell Scanners

Follow these steps to effectively test your oxygen sensors using a Foxwell scanner:

- Connect the Foxwell Scanner: Begin by locating your vehicle’s OBD-II port, typically situated under the dashboard on the driver’s side. Connect the Foxwell scanner to the OBD-II port using the provided cable.

- Turn on the Ignition: Turn the ignition key to the “on” position without starting the engine. This will power up the scanner and establish communication with your vehicle’s ECU.

- Access the Scanner Menu: Navigate through the Foxwell scanner’s menu to locate and select the “Oxygen Sensor” or “O2 Sensor” option.

- Select Sensor Location: Depending on your vehicle model, you may need to specify the location of the oxygen sensor you want to test. Consult your vehicle’s repair manual for guidance.

- Initiate the Test: Once you have selected the desired sensor, initiate the test according to the Foxwell scanner’s instructions. The scanner will send commands to the oxygen sensor and retrieve data.

- Analyze the Results: The Foxwell scanner will display the oxygen sensor readings, including voltage, resistance, and other relevant parameters. Compare these readings to the manufacturer’s specifications to determine if the sensor is functioning within the acceptable range.

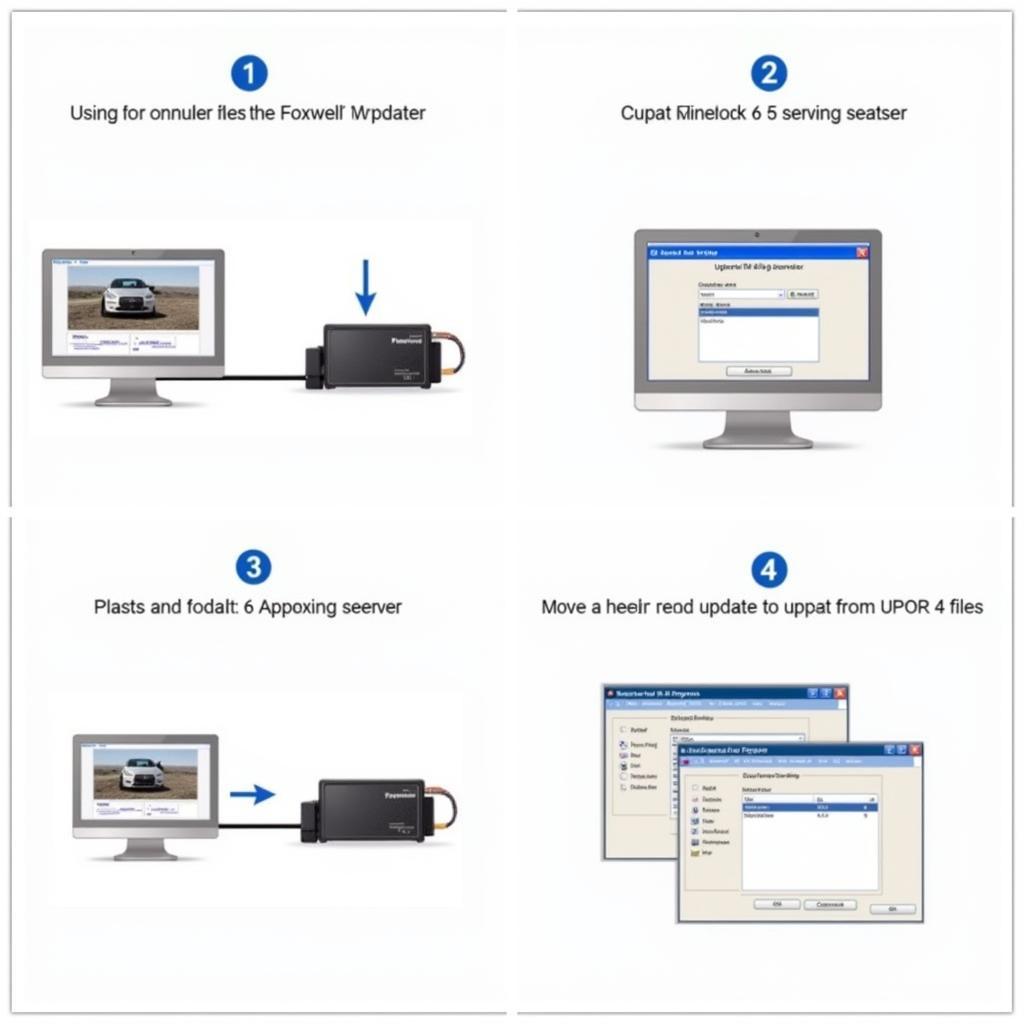

Foxwell Scanner Connected to OBD Port

Foxwell Scanner Connected to OBD Port

Interpreting Oxygen Sensor Readings

Understanding how to interpret oxygen sensor readings is crucial for accurate diagnosis. Here’s a breakdown of common readings and their implications:

- Voltage: A healthy oxygen sensor should fluctuate between 0.1 volts (lean) and 0.9 volts (rich) when the engine is warm and running in closed loop. A sensor stuck at a specific voltage or not fluctuating indicates a problem.

- Resistance: The resistance of the oxygen sensor’s heater circuit can also provide insights into its health. A high resistance value suggests a faulty heater element.

- Response Time: The scanner may also display the sensor’s response time, which indicates how quickly it reacts to changes in oxygen levels. A slow response time can signify a worn-out sensor.

Common Oxygen Sensor Issues and Troubleshooting Tips

- Slow Response Time: This issue is often caused by a contaminated or aging sensor. Cleaning the sensor or replacing it might be necessary.

- Sensor Stuck at a Specific Voltage: A sensor stuck at a high voltage (rich) may indicate a fuel system issue, while a sensor stuck at a low voltage (lean) could point towards a vacuum leak.

- Heater Circuit Malfunction: If the heater circuit is faulty, the sensor may take longer to warm up and provide accurate readings. Replacing the sensor is usually the solution.

Conclusion

Testing oxygen sensors with Foxwell scanners is an effective way to maintain optimal engine performance and fuel efficiency. By understanding how to interpret sensor readings and troubleshoot common issues, you can confidently diagnose and address oxygen sensor problems, saving time and money on costly repairs. If you encounter persistent oxygen sensor issues or need further assistance, it’s always recommended to consult with a qualified automotive technician.

For expert advice and support on Foxwell scanners and automotive diagnostics, contact ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA.

FAQs

Q1: How often should I test my oxygen sensors?

A: It’s generally recommended to have your oxygen sensors inspected every 60,000 miles or as part of your regular vehicle maintenance schedule.

Q2: Can I clean my oxygen sensors?

A: While cleaning oxygen sensors is possible, it’s not always a guaranteed fix. If the sensor is heavily contaminated or damaged, replacement is usually the best course of action.

Q3: Are there different types of oxygen sensors?

A: Yes, there are two main types of oxygen sensors: narrowband and wideband. Narrowband sensors are commonly found in older vehicles, while wideband sensors are prevalent in modern cars.

Q4: What is the difference between upstream and downstream oxygen sensors?

A: Upstream oxygen sensors are located before the catalytic converter and monitor the oxygen content in the exhaust gases entering the converter. Downstream oxygen sensors are positioned after the catalytic converter and measure its efficiency.

Q5: Can I drive with a bad oxygen sensor?

A: While it’s technically possible to drive with a bad oxygen sensor for a short period, it’s not recommended. Driving with a faulty sensor can lead to decreased fuel economy, increased emissions, and potential damage to other engine components.