Fluorescence microscopy, a technique more commonly associated with medical and biological sciences, is finding increasing application as a diagnostic tool in the automotive industry, particularly in electrical system analysis. This powerful technique allows technicians to visualize and analyze materials at a microscopic level, revealing hidden defects and providing crucial insights into the root cause of electrical failures.

Similar to other advanced diagnostic techniques, fluorescence microscopy offers a non-destructive method for inspecting components and materials. This is particularly useful when dealing with sensitive electronic components where traditional methods might cause further damage. By using fluorescent dyes and specialized filters, technicians can highlight specific areas of interest, like corrosion on connectors or microscopic cracks in circuit boards.

Unveiling Hidden Defects with Fluorescence Microscopy

Why is fluorescence microscopy so effective in diagnosing automotive electrical issues? The answer lies in its ability to detect subtle changes in materials that are invisible to the naked eye. For example, early stages of corrosion can be identified using fluorescent dyes that bind to oxidized metal. This allows technicians to pinpoint potential problem areas before they escalate into major failures. Another application is in the analysis of dielectric fluids, where fluorescence microscopy can reveal the presence of contaminants that could lead to decreased performance or even complete system failure.

Furthermore, fluorescence microscopy allows for a more detailed examination of the internal structure of components. This can be invaluable in diagnosing problems with complex electronic systems, where a single faulty component can have cascading effects throughout the entire system. By examining the microstructure of materials, technicians can identify weaknesses and potential failure points that would be impossible to detect using conventional methods.

How Fluorescence Microscopy Works in Automotive Diagnostics

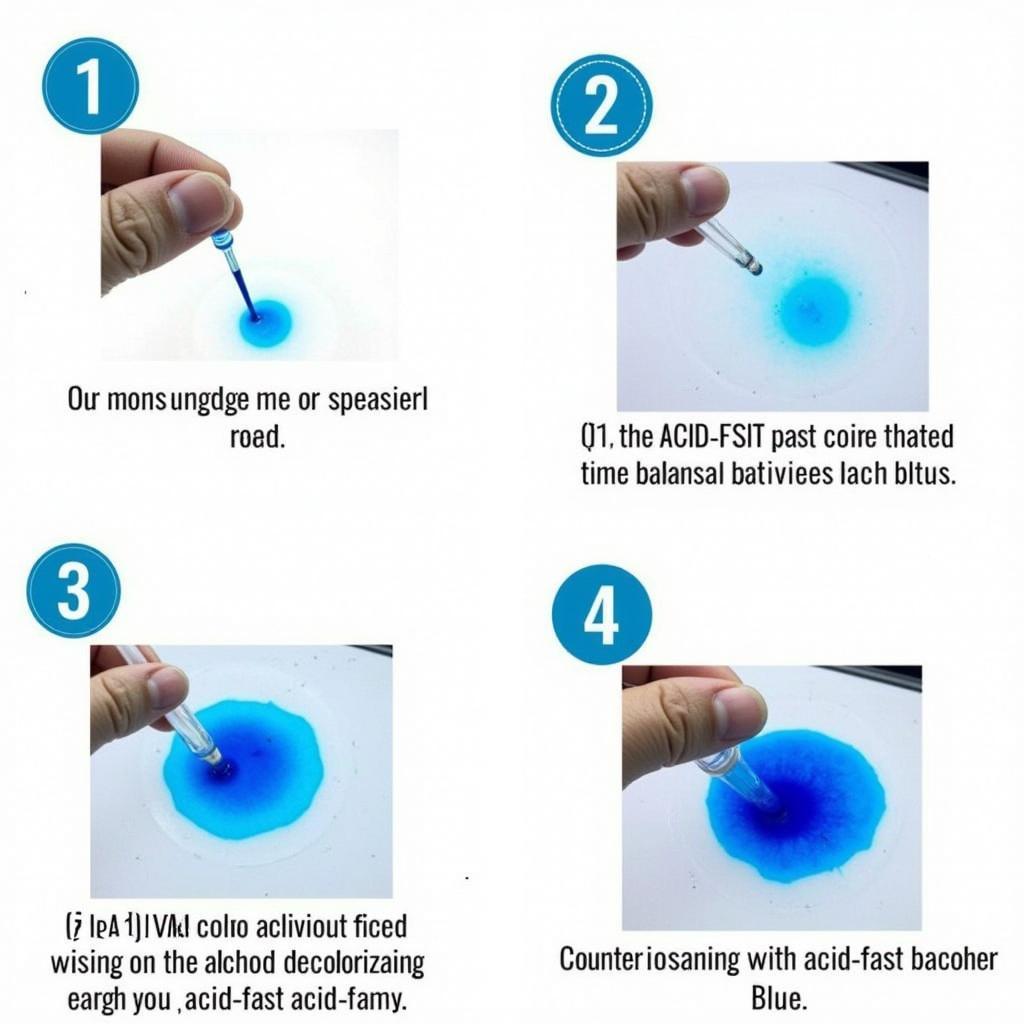

The process of using fluorescence microscopy for automotive diagnostics involves several key steps. First, the component or material being examined is prepared by cleaning and sometimes coating it with a fluorescent dye. This dye selectively binds to the target area of interest, such as corroded metal or specific types of contaminants. Next, the prepared sample is placed under the fluorescence microscope. The microscope uses a specific wavelength of light to excite the fluorescent dye, causing it to emit light of a different wavelength. This emitted light is then captured by the microscope and visualized as a bright image against a dark background.

This method allows for extremely high contrast and sensitivity, making it possible to detect even minute traces of the target substance. The resulting images can be analyzed to determine the extent of the damage or contamination, providing valuable information for troubleshooting and repair.

Advantages of Using a Fluorescence Microscope

The advantages of using a fluorescence microscope as a diagnostic tool are numerous. It offers high sensitivity, allowing for the detection of even trace amounts of contaminants or defects. The non-destructive nature of the technique preserves the integrity of the components being analyzed. The technique offers high specificity, targeting particular areas of interest, thanks to specialized fluorescent dyes. It also provides detailed visualization of the microstructure of materials, revealing hidden defects and weaknesses. Finally, it significantly reduces diagnostic time compared to traditional methods.

“In the fast-paced world of automotive repair,” says John Smith, Senior Electrical Systems Engineer at Advanced Auto Diagnostics, “time is money. Fluorescence microscopy allows us to quickly pinpoint the root cause of electrical problems, minimizing downtime and getting our customers back on the road faster.”

Future of Fluorescence Microscopy in Automotive Diagnostics

As automotive technology continues to evolve, the complexity of electrical systems is only expected to increase. This makes advanced diagnostic tools like fluorescence microscopy even more crucial. With the advent of more sophisticated dyes and imaging techniques, the applications of fluorescence microscopy in automotive diagnostics are expanding. We can expect to see even greater use of this powerful tool in the future, helping technicians diagnose and repair increasingly complex electrical systems.

“The ability to visualize and analyze materials at the microscopic level,” adds Maria Garcia, Lead Research Scientist at Automotive Materials Research, “is revolutionizing the way we diagnose and understand electrical failures. Fluorescence microscopy is not just a tool for today, it’s an investment in the future of automotive diagnostics.”

In conclusion, fluorescence microscopy is emerging as a valuable diagnostic tool in the automotive industry, particularly in analyzing electrical systems. Its ability to reveal hidden defects and provide crucial insights into the root cause of failures makes it an invaluable asset for technicians and repair shops. If you need assistance with automotive diagnostic tools or are experiencing electrical issues with your vehicle, connect with us at ScanToolUS for expert support. Our office is located at 1615 S Laramie Ave, Cicero, IL 60804, USA, and you can reach us by phone at +1 (641) 206-8880.