3D scan tools are rapidly transforming the automotive repair landscape, offering unprecedented accuracy and efficiency in diagnosing and fixing vehicle issues. From minor dents to complex structural damage, these cutting-edge tools empower technicians with the ability to capture precise measurements and create detailed 3D models of vehicles, facilitating faster, more effective repairs. This technology is not just a futuristic concept; it’s a present-day reality that’s reshaping how we approach auto repair, both for independent shops and larger dealerships.

How 3D Scan Tools Enhance Automotive Diagnostics

Traditionally, diagnosing vehicle damage relied heavily on visual inspection and manual measurements, a process prone to human error and often time-consuming. 3D scan tools eliminate these limitations by providing a comprehensive digital representation of the vehicle. This detailed scan data allows technicians to pinpoint even the smallest imperfections, accurately assess the extent of damage, and develop precise repair plans.

What are the benefits of using 3D scan tools for diagnostics? They offer unparalleled accuracy, reducing the risk of misdiagnosis and ensuring that repairs are targeted effectively. This precision saves valuable time and resources, streamlining the entire repair process.

Streamlining Collision Repair with 3D Scanning Technology

3D scan tools are particularly impactful in collision repair. By capturing the precise contours of a damaged vehicle, these tools enable technicians to create a digital blueprint for repair, ensuring that replacement parts fit perfectly and that the vehicle’s structural integrity is restored to pre-accident condition.

How do 3D scan tools improve collision repair efficiency? They eliminate the need for repeated adjustments and rework, significantly reducing repair times and getting vehicles back on the road faster. This enhanced efficiency translates to cost savings for both repair shops and vehicle owners.

3D Scan Tool in Collision Repair: Assessing Vehicle Damage

3D Scan Tool in Collision Repair: Assessing Vehicle Damage

Beyond Collision: Expanding Applications of 3D Scan Tools

While their application in collision repair is well-established, 3D scan tools are increasingly being utilized in other areas of automotive repair. From aligning chassis components to creating custom parts, these versatile tools are proving their value across a range of applications. They can also be used for reverse engineering parts, creating digital archives of classic cars, and even in vehicle design and development.

What are some emerging uses of 3D scan tools? They are being integrated into advanced driver-assistance systems (ADAS) calibration, ensuring accurate sensor placement and optimal system performance. They are also being used for quality control in manufacturing, ensuring that parts meet precise specifications.

Choosing the Right 3D Scan Tool for Your Needs

The market offers a variety of 3D scan tools, each with its own strengths and limitations. Selecting the right tool depends on your specific needs and budget. Factors to consider include the level of accuracy required, the size and complexity of the objects being scanned, and the software compatibility with your existing systems.

What are the key factors to consider when selecting a 3D scan tool? Portability, ease of use, and data processing capabilities are important considerations. Additionally, consider the availability of training and technical support from the manufacturer.

Portable 3D Scanner for Auto Repair: Quick and Accurate Assessments

Portable 3D Scanner for Auto Repair: Quick and Accurate Assessments

“Investing in 3D scanning technology is a game-changer for any auto repair shop. It not only enhances accuracy and efficiency but also builds customer trust by demonstrating a commitment to cutting-edge technology,” says John Miller, Senior Automotive Technician at Miller’s Auto Repair.

Maximizing the Value of Your 3D Scan Tool Investment

To fully realize the benefits of 3D scan tools, proper training and implementation are essential. Technicians need to be proficient in using the scanning software and interpreting the data. Integrating the technology into existing workflows and ensuring data security are also crucial steps for successful implementation.

How can you maximize the ROI of your 3D scan tool? Regular software updates, ongoing training, and collaboration with other users can help ensure that you’re getting the most out of your investment.

“3D scan tools are not just about speed; they’re about precision and quality. They allow us to deliver a higher level of service to our customers and ensure that repairs are done right the first time,” adds Sarah Chen, Lead Collision Repair Technician at City Collision Center.

Conclusion: Embracing the Future of Auto Repair with 3D Scan Tools

3D scan tools are revolutionizing the auto repair industry, offering unmatched accuracy, efficiency, and versatility. From diagnosing minor dents to reconstructing complex damage, these tools are transforming how we approach vehicle repair. By embracing this technology, repair shops and technicians can enhance their capabilities, improve customer satisfaction, and stay ahead of the curve in the ever-evolving automotive landscape. Connect with us at ScanToolUS for more information and support. Our phone number is +1 (641) 206-8880, and our office is located at 1615 S Laramie Ave, Cicero, IL 60804, USA. We are ready to help you navigate the world of 3d scan tools.

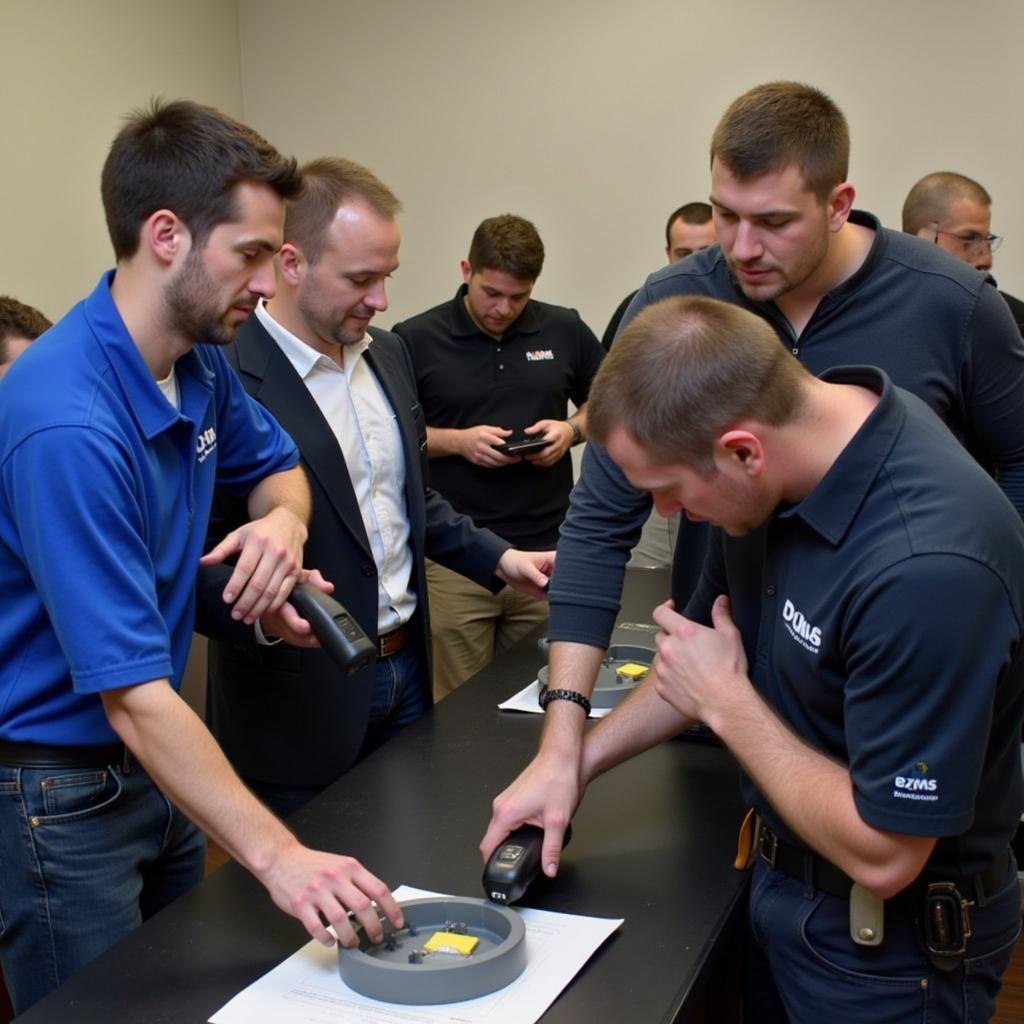

3D Scan Tool Training Workshop: Enhancing Technician Skills

3D Scan Tool Training Workshop: Enhancing Technician Skills

FAQ

- How much do 3D scan tools cost? The cost varies depending on features and capabilities, ranging from a few thousand dollars to tens of thousands of dollars.

- What type of training is required to use 3D scan tools effectively? Manufacturers often provide training programs, and online resources are also available.

- Are 3D scan tools difficult to use? While they require some technical knowledge, most systems are designed to be user-friendly with intuitive software interfaces.

- What are the main advantages of using 3D scan tools over traditional methods? Increased accuracy, reduced repair times, and improved customer satisfaction are key benefits.

- Can 3D scan tools be used on all types of vehicles? Yes, they can be used on cars, trucks, motorcycles, and even heavy equipment.

- How long does it take to scan a vehicle with a 3D scanner? The scanning time depends on the size and complexity of the vehicle, but it can often be completed in under an hour.

- What software is used with 3D scan tools? Various software packages are available, offering different features and functionalities for data processing and analysis.