A failing crankshaft position sensor can cause a variety of drivability issues, from rough idling to a complete no-start. When replacing this sensor, a crankshaft position relearn procedure is often necessary. This requires a Scan Tool That Can Perform Crankshaft Position Relearn. Let’s explore the importance of this procedure, the types of scan tools available, and how to choose the right one for your needs.

The crankshaft position sensor plays a vital role in your vehicle’s engine management system. It provides crucial information to the engine control unit (ECU) about the crankshaft’s position and speed. This data allows the ECU to precisely control fuel injection and ignition timing. Without accurate readings from the crankshaft position sensor, the engine can misfire, run rough, or even fail to start. When a new crankshaft position sensor is installed, the ECU often needs to relearn the sensor’s characteristics. This is where a scan tool that can perform crankshaft position relearn becomes essential.

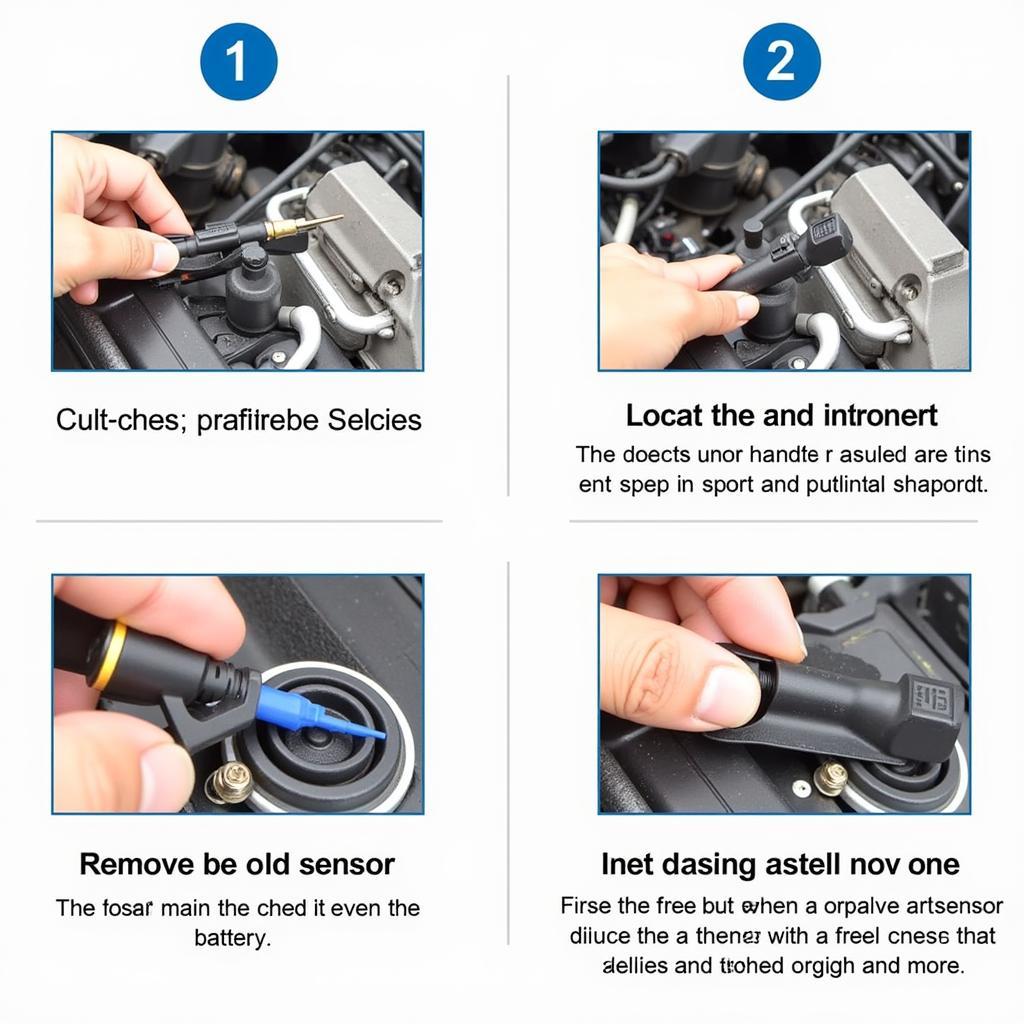

Crankshaft Position Sensor Replacement Procedure

Crankshaft Position Sensor Replacement Procedure

What types of scan tools can perform this function? There are numerous scan tools on the market, ranging from basic code readers to advanced professional-grade diagnostic tools. Basic code readers can retrieve diagnostic trouble codes (DTCs) but typically lack the capability to perform a crankshaft position relearn. For this procedure, you’ll need a more advanced scan tool, often referred to as a bidirectional scan tool. These tools can communicate with the ECU, allowing you to access and control various vehicle systems, including performing relearn procedures.

How to choose the right scan tool for crankshaft position relearn? Consider your specific needs and budget. If you’re a professional technician, investing in a high-end scan tool with extensive capabilities is worthwhile. However, if you’re a DIY enthusiast, a mid-range scan tool with crankshaft relearn functionality might be sufficient. Similar to [scan tool crankshaft relearn], other relearn procedures might be needed after certain repairs. Some important features to look for include vehicle coverage, ease of use, software updates, and technical support.

Scan Tool Performing Crankshaft Relearn

Scan Tool Performing Crankshaft Relearn

Why is crankshaft position relearn so important? Without this procedure, the ECU may not recognize the new sensor, leading to continued performance issues. The engine may still run rough, misfire, or have difficulty starting. A successful crankshaft position relearn ensures that the ECU and the new sensor are synchronized, allowing the engine to run smoothly and efficiently. What are the common symptoms that indicate a crankshaft relearn is needed? Rough idling, misfires, difficulty starting, and a check engine light are all common indicators.

Can you perform a crank relearn without a scan tool? In some cases, yes. However, the specific procedures vary depending on the vehicle’s make and model. Consult your vehicle’s repair manual for detailed instructions. This process often involves specific driving cycles or other manipulations that can be complex. Using a scan tool is generally the recommended and most reliable method. As you explore options, understanding how to use [using harbor freight scan tool] can be beneficial.

“A properly performed crankshaft position relearn is crucial for optimal engine performance after sensor replacement,” says Robert Johnson, a seasoned automotive technician with over 20 years of experience. “It ensures the engine control unit recognizes the new sensor and operates the engine efficiently.”

What are some common mistakes to avoid during the procedure? One common mistake is using an incompatible scan tool. Ensure the scan tool you choose is compatible with your vehicle’s make and model. Another common error is interrupting the relearn procedure before completion. Follow the instructions carefully and ensure the process is finished without interruption. Remember that an [idle relearn without scan tool] may also be necessary in certain situations.

Mechanic Connecting Scan Tool to Car's OBD Port

Mechanic Connecting Scan Tool to Car's OBD Port

“Investing in a quality scan tool with crankshaft relearn functionality can save you time and money in the long run,” adds Maria Garcia, an automotive electronics specialist. “It empowers you to accurately diagnose and resolve sensor issues without relying solely on guesswork.” This also applies to scenarios like needing an [ibe scan tool] for specific diagnostics.

In conclusion, a scan tool that can perform crankshaft position relearn is a valuable tool for both professional technicians and DIY enthusiasts. It enables accurate diagnosis and efficient repair of crankshaft position sensor issues, ensuring optimal engine performance. By understanding the importance of this procedure and choosing the right scan tool, you can keep your vehicle running smoothly for years to come. For further assistance with crankshaft position relearn or scan tool selection, feel free to connect with us at ScanToolUS. You can reach us by phone at +1 (641) 206-8880 or visit our office located at 1615 S Laramie Ave, Cicero, IL 60804, USA. We can also provide guidance if you’re looking for information on a [crank relearn procedure without scan tool].