The Thomas Bus Diagnostic Tool is an essential piece of equipment for anyone working with Thomas Built Buses. Whether you’re a fleet manager, a technician, or a DIY enthusiast, understanding how to use this tool can save you time, money, and frustration. This guide will walk you through everything you need to know about diagnosing and troubleshooting Thomas buses with the appropriate diagnostic tool.

Understanding the Importance of Thomas Bus Diagnostics

Regular diagnostics are crucial for maintaining the health and safety of your Thomas bus fleet. Early detection of potential issues can prevent costly repairs and downtime. Using a Thomas bus diagnostic tool allows you to pinpoint problems quickly and accurately, avoiding guesswork and unnecessary part replacements.

Why Choose a Dedicated Thomas Bus Diagnostic Tool?

While generic OBD-II scanners can read some basic codes, a dedicated Thomas bus diagnostic tool provides access to manufacturer-specific information, including body controller data, proprietary fault codes, and real-time sensor readings. This deeper level of insight allows for more comprehensive diagnostics and more efficient repairs.

Selecting the Right Thomas Bus Diagnostic Tool

The market offers various Thomas bus diagnostic tools, each with its own features and capabilities. Consider factors like software updates, compatibility with different Thomas bus models, and ease of use when making your selection. Investing in a high-quality tool with comprehensive software and regular updates is essential for long-term success.

Key Features to Look For:

- Comprehensive Fault Code Coverage: The tool should be able to read and interpret all relevant fault codes, including manufacturer-specific codes.

- Live Data Streaming: Real-time data from various sensors allows for dynamic diagnostics and monitoring of system performance.

- Bi-directional Controls: This feature enables you to activate various components, such as actuators and relays, to test their functionality.

- User-Friendly Interface: An intuitive interface simplifies the diagnostic process and reduces the learning curve.

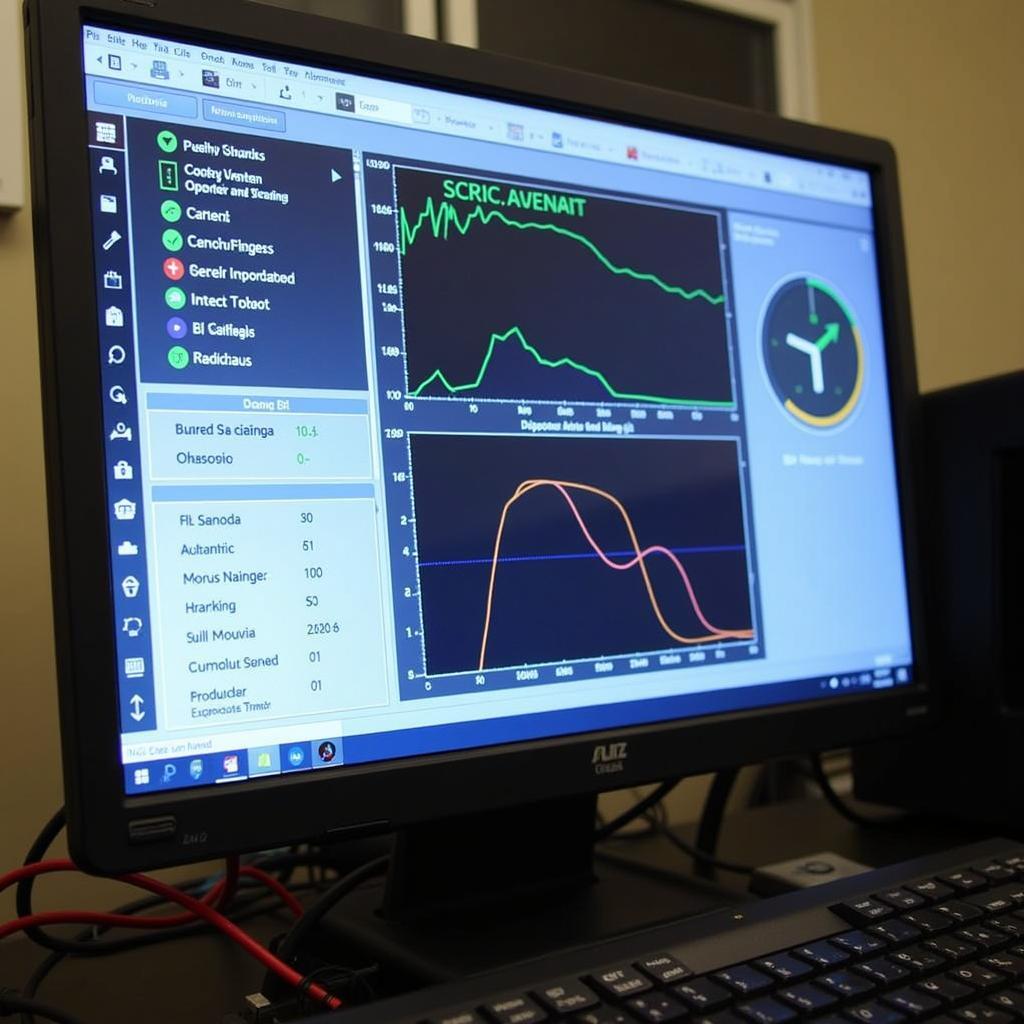

Screenshot of the Thomas bus diagnostic software interface showing diagnostic data.

Screenshot of the Thomas bus diagnostic software interface showing diagnostic data.

Troubleshooting Common Thomas Bus Problems with a Diagnostic Tool

A Thomas bus diagnostic tool can be used to diagnose a wide range of issues, including:

- Engine Performance Problems: Identify problems with fuel delivery, ignition, and emissions control systems.

- Transmission Issues: Diagnose problems with shifting, clutch operation, and torque converter performance.

- Brake System Faults: Detect issues with ABS, air brakes, and hydraulic brake systems.

- Electrical Problems: Troubleshoot issues with wiring, sensors, and electronic control modules.

- Body Controller Issues: Diagnose problems with lighting, door controls, and other body systems.

Interpreting Diagnostic Trouble Codes (DTCs)

Understanding DTCs is essential for effective troubleshooting. While the diagnostic tool will provide the code, it’s important to know what each code means and how to address the underlying problem. Consult service manuals or online resources for detailed information on specific DTCs.

“A good diagnostic tool is like having an extra set of eyes and ears. It allows you to see what’s happening inside the bus’s systems and understand the root cause of problems.” – John Miller, Senior Automotive Technician

Tips for Effective Thomas Bus Diagnostics

- Always consult the service manual: This invaluable resource provides detailed information about the specific systems and components of your bus.

- Update your diagnostic software regularly: This ensures compatibility with the latest Thomas bus models and provides access to the most up-to-date diagnostic information.

- Keep a record of diagnostic results: This can be helpful for tracking recurring issues and identifying patterns.

- Don’t hesitate to seek expert help: If you’re unsure about a particular diagnosis or repair, it’s always best to consult a qualified technician.

“Investing in a quality Thomas bus diagnostic tool and proper training is a smart move for any fleet operator. It pays for itself in reduced downtime and repair costs.” – Maria Rodriguez, Fleet Maintenance Manager

Conclusion

The Thomas bus diagnostic tool is an indispensable tool for anyone responsible for maintaining and repairing Thomas buses. By understanding how to use this tool effectively, you can ensure the safety, reliability, and longevity of your fleet. For any further assistance or inquiries, feel free to connect with ScanToolUS at +1 (641) 206-8880 or visit our office located at 1615 S Laramie Ave, Cicero, IL 60804, USA.

A complete Thomas bus diagnostic tool kit with various cables and connectors.

A complete Thomas bus diagnostic tool kit with various cables and connectors.

FAQ

- What is the best Thomas bus diagnostic tool? The “best” tool depends on your specific needs and budget. Consider factors like software updates, compatibility, and features.

- How often should I perform diagnostics on my Thomas bus? Regular diagnostics, ideally every few months or before long trips, are recommended.

- Can I use a generic OBD-II scanner on a Thomas bus? While a generic scanner can read some basic codes, a dedicated Thomas bus diagnostic tool is recommended for comprehensive diagnostics.

- Where can I find training on using a Thomas bus diagnostic tool? Several online resources and training programs are available for learning how to use these tools.

- What should I do if I can’t interpret a diagnostic trouble code? Consult the service manual or contact a qualified technician for assistance.

- How much does a Thomas bus diagnostic tool cost? Prices vary depending on features and capabilities, ranging from a few hundred to several thousand dollars.

- Where can I buy a Thomas bus diagnostic tool? Diagnostic tools are available from various online retailers and automotive parts suppliers.