Liebherr Diagnostic Tools are essential for effectively troubleshooting and maintaining Liebherr machinery. From construction equipment to mining trucks, these specialized tools provide in-depth insights into the intricate systems that power these complex machines. Understanding how to use these tools is crucial for both individual owners and professional technicians. This guide will delve into the various aspects of Liebherr diagnostic tools, providing you with the knowledge to diagnose and resolve issues efficiently.

Why Liebherr Diagnostic Tools Are Essential

Modern Liebherr machinery incorporates sophisticated electronic control units (ECUs) that manage various functions, from engine performance to hydraulic systems. Liebherr diagnostic tools provide a direct interface with these ECUs, allowing you to access vital data, identify fault codes, and perform advanced diagnostics. This capability is invaluable for minimizing downtime and optimizing machine performance. Imagine trying to pinpoint a problem within a complex hydraulic system without the proper diagnostic tools – it would be like searching for a needle in a haystack.

Understanding the Range of Liebherr Diagnostic Tools

Liebherr offers a range of diagnostic tools tailored to different needs and levels of expertise. These tools vary in their capabilities, from basic code readers to comprehensive diagnostic suites. Some popular options include the Liebherr Diagnostic Software (LIDOS) and the mobile diagnostic app. Choosing the right tool depends on the specific machinery you’re working with and the depth of diagnostic information you require.

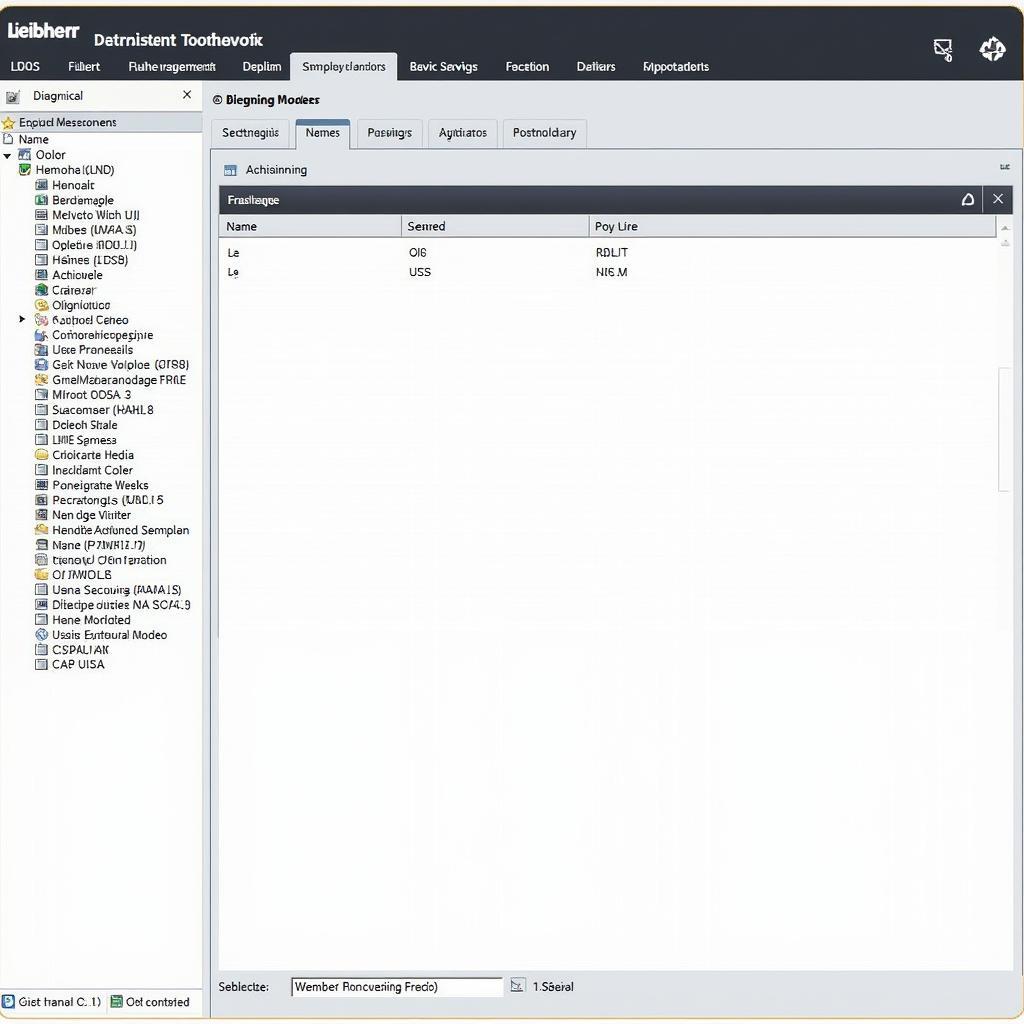

Liebherr Diagnostic Software (LIDOS) Interface

Liebherr Diagnostic Software (LIDOS) Interface

How to Use Liebherr Diagnostic Tools Effectively

Using Liebherr diagnostic tools effectively requires a combination of technical knowledge and practical experience. First, you need to connect the tool to the machine’s diagnostic port. Once connected, the tool will communicate with the ECUs, retrieving data and displaying it in a user-friendly format. You can then navigate through different menus and functions to access specific information, such as fault codes, sensor readings, and system parameters.

Interpreting Diagnostic Data

Interpreting the data retrieved from Liebherr diagnostic tools is crucial for accurate diagnosis. Understanding fault codes and their associated meanings is essential. Cross-referencing these codes with service manuals and technical documentation will provide a detailed understanding of the underlying issue. Furthermore, analyzing sensor readings and system parameters can reveal subtle anomalies that might indicate potential problems.

Interpreting Liebherr Diagnostic Data

Interpreting Liebherr Diagnostic Data

Advanced Diagnostic Techniques with Liebherr Tools

Beyond basic code reading, Liebherr diagnostic tools offer advanced functionalities like component activation, parameter adjustments, and calibration procedures. These capabilities enable technicians to perform in-depth troubleshooting and fine-tune machine performance. However, these advanced features require a higher level of expertise and should be used with caution.

“Using Liebherr diagnostic tools correctly can significantly reduce diagnostic time and improve the accuracy of repairs,” says Peter Schmidt, a seasoned heavy equipment technician with over 20 years of experience. “It’s like having an X-ray vision into the machine’s inner workings.”

Maintaining Your Liebherr Diagnostic Tools

Regular updates and maintenance are crucial for ensuring the accuracy and reliability of your Liebherr diagnostic tools. Software updates often include new features, bug fixes, and compatibility improvements. Keeping your tools up-to-date is vital for staying ahead of evolving technology and maintaining optimal diagnostic performance.

Troubleshooting Common Issues with Liebherr Diagnostic Tools

Occasionally, you might encounter issues with your Liebherr diagnostic tools, such as connection problems or communication errors. Troubleshooting these issues requires a systematic approach. Check the physical connections, ensure the software is up-to-date, and consult the troubleshooting section of the user manual. If the problem persists, contacting Liebherr technical support can provide further assistance.

“Remember, proper training is key to effectively using Liebherr diagnostic tools,” adds Maria Sanchez, a certified Liebherr technician and trainer. “Understanding the intricacies of the software and the machine’s systems will allow you to leverage the full potential of these powerful diagnostic tools.”

Conclusion

Liebherr diagnostic tools are indispensable for anyone working with Liebherr machinery. Understanding their capabilities and utilizing them effectively is crucial for efficient troubleshooting, maintenance, and performance optimization. By mastering these tools, you can significantly reduce downtime and ensure the smooth operation of your Liebherr equipment. Connect with ScanToolUS at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA for any assistance or further information regarding Liebherr diagnostic tools.

FAQ

- What are the different types of Liebherr diagnostic tools available?

- How do I connect a Liebherr diagnostic tool to my machine?

- Where can I find information about Liebherr fault codes?

- How often should I update my Liebherr diagnostic software?

- What should I do if my Liebherr diagnostic tool is not working correctly?

- Can I use Liebherr diagnostic tools on other brands of machinery?

- Where can I get training on using Liebherr diagnostic tools?