Construction Crane Equipment Diagnostics Tools are essential for ensuring the smooth operation and longevity of these powerful machines. Whether you’re a crane owner, a fleet manager, or a seasoned technician, having access to the right diagnostic equipment and understanding how to use it effectively can save you time, money, and potential headaches down the road.

Why Invest in Construction Crane Equipment Diagnostics?

Modern construction cranes are complex systems, relying on a delicate interplay of mechanical, hydraulic, and electronic components. When something goes wrong, pinpointing the root cause can be like finding a needle in a haystack without the right tools. This is where construction crane equipment diagnostics come into play.

Here are just a few benefits of utilizing diagnostic tools:

- Early Problem Detection: Diagnostic tools can identify minor issues before they escalate into major (and costly) repairs.

- Reduced Downtime: By quickly identifying and addressing problems, you can minimize downtime and keep your projects on schedule.

- Accurate Troubleshooting: Guesswork is eliminated with concrete data, leading to more efficient repairs.

- Improved Safety: Proactive maintenance through diagnostics ensures that your crane operates at peak safety standards, protecting both your equipment and your crew.

Types of Construction Crane Equipment Diagnostics Tools

There is a wide range of diagnostic tools available, from handheld devices to sophisticated software suites. Here are some of the most common types:

1. On-Board Diagnostics (OBD) Scanners:

OBD scanners are essential for reading and interpreting fault codes generated by a crane’s electronic control unit (ECU). These codes provide valuable insights into the health of the engine, transmission, and other critical systems.

Crane OBD Scanner

Crane OBD Scanner

2. Pressure Gauges:

Hydraulic systems are the backbone of most cranes, and pressure gauges are vital for monitoring their performance. By measuring pressure at various points in the system, technicians can identify leaks, blockages, or failing components.

3. Multimeters:

Multimeters are versatile tools used to measure voltage, current, and resistance in electrical circuits. They are essential for diagnosing electrical faults, testing sensors, and troubleshooting wiring issues.

4. Data Loggers:

Data loggers continuously monitor and record various parameters such as engine temperature, oil pressure, and operating hours. This data is invaluable for identifying trends, predicting potential failures, and optimizing maintenance schedules.

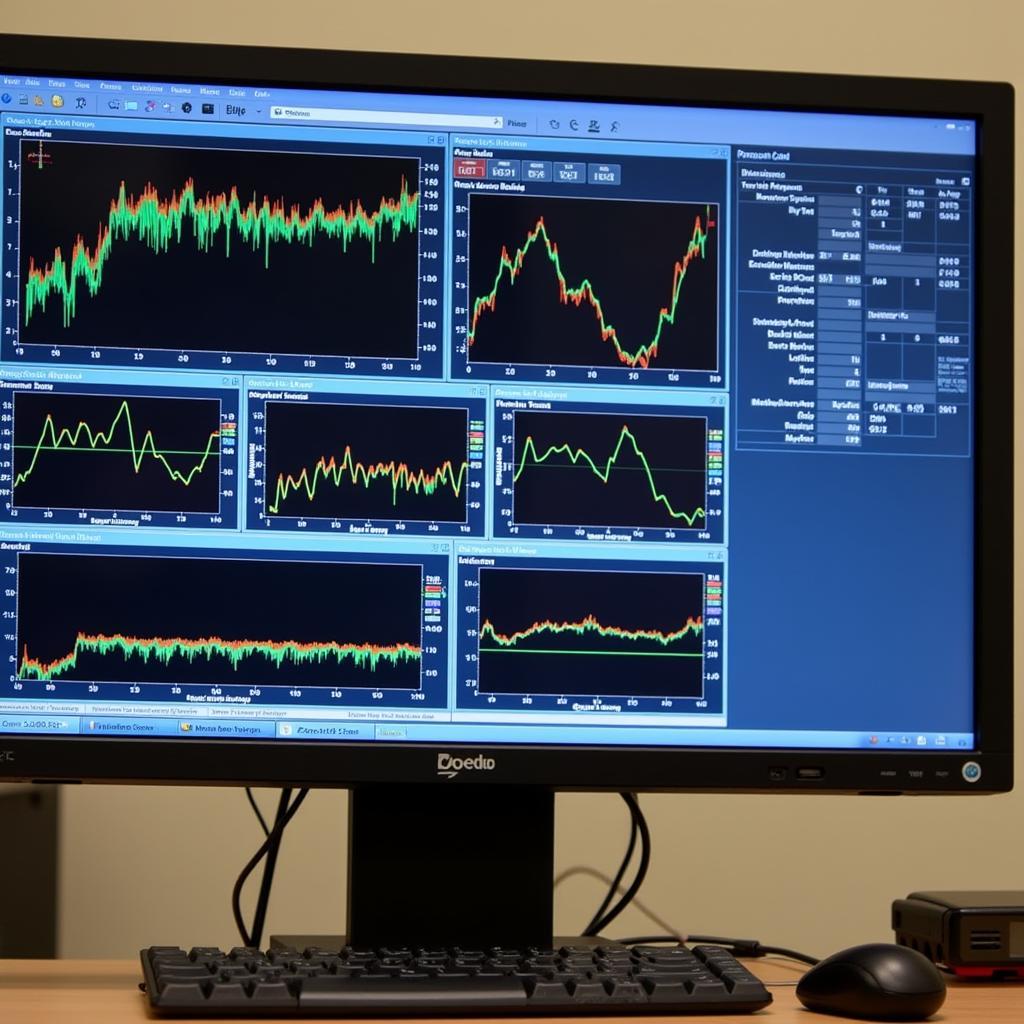

Crane Data Logger Analysis

Crane Data Logger Analysis

5. Software-Based Diagnostic Platforms:

Advanced software programs offer a comprehensive suite of diagnostic capabilities, often combining data from multiple sensors and systems. These platforms can provide real-time insights, generate detailed reports, and even offer remote diagnostic support.

Choosing the Right Construction Crane Equipment Diagnostic Tool

Selecting the right diagnostic tools depends on several factors, including:

- Crane Type and Age: Different cranes have different diagnostic requirements. Older models may rely on simpler tools, while newer cranes may require more advanced software-based solutions.

- Budget: Diagnostic tools range in price from affordable handheld devices to high-end systems.

- Technical Expertise: The complexity of the diagnostic tools should align with the skill level of the user.

“It’s important to invest in diagnostic tools that are compatible with your specific crane models and provide the level of detail you need for effective troubleshooting,” advises John Miller, a senior crane technician with over 20 years of experience. “Don’t underestimate the value of ongoing training to keep your skills sharp as diagnostic technology evolves.”

The Future of Construction Crane Equipment Diagnostics

The field of construction crane equipment diagnostics is constantly evolving. Here are some trends shaping the future:

- Increased Connectivity: Telematics and cloud-based solutions are enabling remote diagnostics and predictive maintenance, further reducing downtime and improving efficiency.

- Artificial Intelligence (AI): AI algorithms are being integrated into diagnostic platforms to analyze vast amounts of data, identify patterns, and provide even more accurate predictions and insights.

- Augmented Reality (AR): AR technology is being used to overlay diagnostic information onto the real-world view of the crane, assisting technicians in identifying and repairing problems more intuitively.

Conclusion

Construction crane equipment diagnostics tools are indispensable for anyone involved in the operation and maintenance of these complex machines. By investing in the right tools and staying informed about the latest advancements, you can ensure the optimal performance, safety, and longevity of your cranes.

Need help choosing the right construction crane equipment diagnostics tools for your needs? Contact the experts at ScanToolUS today at +1 (641) 206-8880 or visit our office at 1615 S Laramie Ave, Cicero, IL 60804, USA. We’re here to help you find the perfect solution for your diagnostic needs.